CONTENT

General Information

-How To Use This Manual

-Important Safety Instructions

-General Service Information

-Standard Workshop Practices

-Health and Safety Precautions

-Solvents, Sealants and Adhesives

-Road/Roller Testing

-Special Tool Glossary

Identification Codes

-Description and Operation

Jacking and Lifting Description and Operation

-Jacking

-Lifting

-Vehicle Recovery

Maintenance Schedules Description and Operation

-Maintenance Schedules – Gasoline Engines

-Maintenance Schedules – Diesel Engines

CHASSIS

Suspension System – General Information

-Specifications

-General Procedures

-Four -Wheel Alignment

Front Suspension

-Specifications

-General Procedures

-Description and Operation:

– Front Suspension

– Removal and Installation

– Stabilizer Bar

– Stabilizer Bar Link

– Upper Arm Ball Joint

– Lower Arm Ball Joint

– Wheel Knuckle

– Wheel Bearing and Wheel Hub

– Shock Absorber and Spring Assembly

– Upper Arm

– Lower Arm

– Upper Arm Bushing

– Lower Arm Bushing

Rear Suspension

-Specifications

-Description and Operation:

– Rear Suspension

-Removal and Installation:

– Upper Arm Ball Joint

– Lower Arm Ball Joint

– Wheel Bearing and Wheel Hub

– Shock Absorber and Spring Assembly

– Stabilizer Bar

– Wheel Knuckle

– Upper Arm Bushing

– Stabilizer Bar Link

– Lower Arm

– Upper Arm

– Toe Link

– Lower Arm Bushing

Wheels and Tires

-Specifications

-Description and Operation:

– Wheels and Tires

-Removal and Installation:

– Tire Low Pressure Sensor

– Tire Pressure Monitoring System Front Antenna

– Tire Pressure Monitoring System Rear Antenna

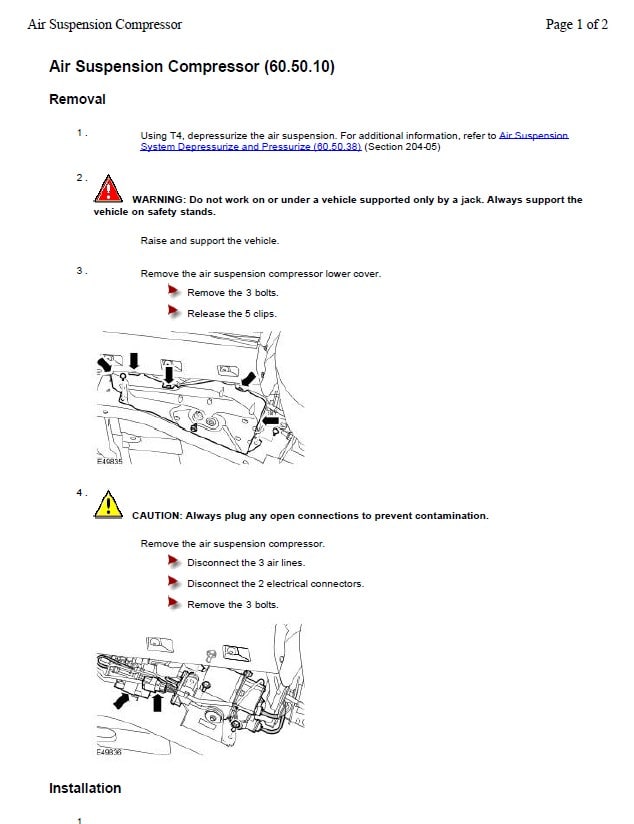

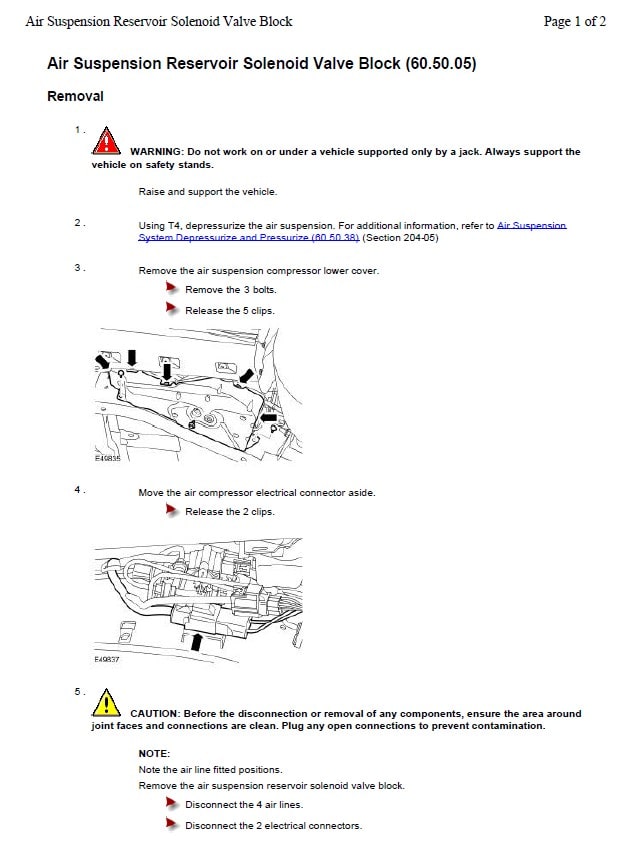

Vehicle Dynamic Suspension

-Specifications

-General Procedures:

– Air Suspension System Depressurize and Pressurize

– Ride Height Adjustments

-Description and Operation:

– Vehicle Dynamic Suspension

-Removal and Installation:

– Suspension Height Sensor

– Air Suspension Reservoir

– Air Suspension Control Module

– Air Suspension Reservoir Solenoid Valve Block

– Air Suspension Compressor Drier

– Air Suspension Compressor

– Air Suspension Front Solenoid Valve Block

– Air Suspension Muffler

– Air Suspension Rear Solenoid Valve Block

– Air Suspension Air Filter

– Front Air Shock Absorber

– Rear Air Shock Absorber

– Front Shock Absorber and Air Spring Assembly

– Rear Shock Absorber and Air Spring Assembly

Ride and Handling Optimization

-Description and Operation:

– Ride and Handling Optimization

-Removal and Installation:

– Ride and Handling Optimization Switch

-Driveline

Driveline System

-General Information

Driveshaft

-Specifications

-Description and Operation:

– Driveshaft

– Universal Joints

-Removal and Installation:

– Front Driveshaft – 4.4L

– Front Driveshaft – 4.0L

– Front Driveshaft – 2.7L Diesel

– Rear Driveshaft

Rear Drive Axle/Differential

-Specifications

-General Procedures:

– Differential Draining and Filling

-Description and Operation:

– Rear Drive Axle and Differential

-Removal and Installation:

– Axle Assembly

– Axle Housing Bushing

– Rear Axle Housing Support Insulator

-In Vehicle Repair:

– Differential Locking Motor

– Rear Axle Oil Temperature Sensor

– Drive Pinion Seal

– Differential Locking Module

Front Drive Axle/Differential

-Specifications

-General Procedures:

– Differential Draining and Filling

-Description and Operation:

– Front Drive Axle and Differential

-Removal and Installation:

– Axle Assembly

– Axle Carrier Bushing

-In Vehicle Repair:

– Drive Pinion Seal

– Front Axle Housing Support Insulator

– Axle Tube

Front Drive Halfshafts

-Specifications

-Description and Operation:

– Front Drive Halfshafts

– Halfshaft Joint

-Removal and Installation:

– Halfshaft LH

– Halfshaft RH

– Outer Constant Velocity (CV) Joint Boot

– Inner Constant Velocity (CV) Joint Boot

Rear Drive Halfshafts

-Specifications

-Description and Operation

– Rear Drive Halfshafts

-Removal and Installation

– Halfshaft

– Outer Constant Velocity (CV) Joint Boot

– Inner Constant Velocity (CV) Joint Boot

– Halfshaft Bearing

BRAKE SYSTEM

Brake System

-General Information

-Specifications

-General Procedures:

– Brake System Bleeding

– Brake System Pressure Bleeding

– Front Brake Disc Runout Check

– Rear Brake Disc Runout Check

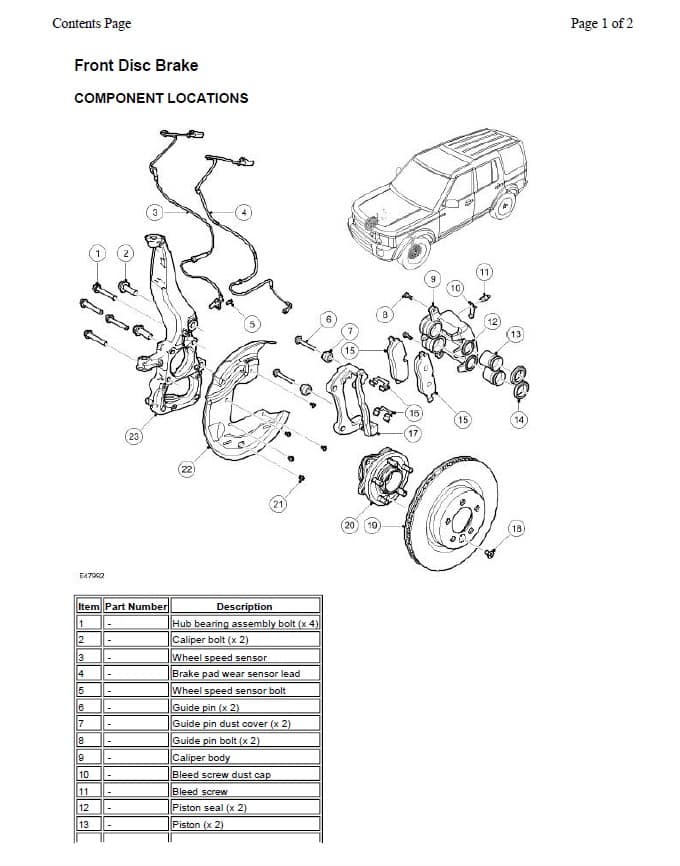

Front Disc Brake

-Specifications

-Description and Operation:

– Front Disc Brake

-Removal and Installation:

– Brake Disc

– Brake Pads

– Brake Caliper

Rear Disc Brake

-Specifications

-Description and Operation:

– Rear Disc Brake

-Removal and Installation:

– Brake Disc

– Brake Pads

– Brake Caliper

– Brake Caliper Anchor Plate

Parking Brake and Actuation

-Specifications

-General Procedures:

– Parking Brake Shoe and Lining Adjustment

– Parking Brake Shoes Bedding-In

-Description and Operation:

– Parking Brake

-Removal and Installation:

– Parking Brake Cable

– Parking Brake Switch

– Parking Brake Actuator – 2.7L Diesel

– Parking Brake Actuator – 4.0L/4.4L

– Shoes

Hydraulic Brake Actuation

-Specifications

-Description and Operation:

– Hydraulic Brake Actuation

-Removal and Installation:

– Brake Fluid Reservoir

– Brake Master Cylinder

– Brake Pedal – Vehicles With: Automatic Transmission

– Brake Pedal and Bracket – Vehicles With: Manual Transmission

– Brake Pedal and Bracket – Vehicles With: Automatic Transmission

Power Brake Actuation

-Specifications

-Description and Operation:

– Brake Booster

-Removal and Installation:

– Brake Booster

– Brake Vacuum Pump – 2.7L Diesel

– Brake Vacuum Pump – 4.0L/4.4L

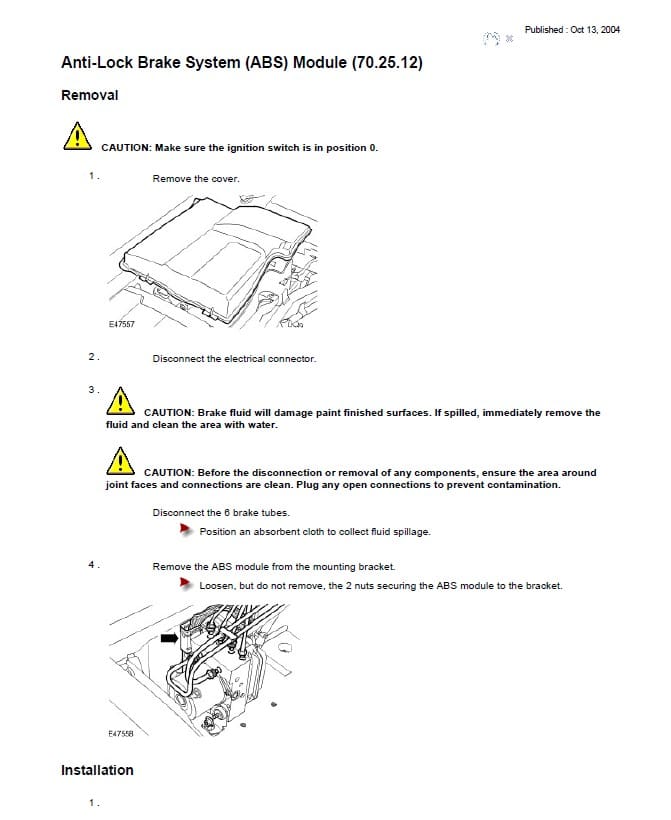

Anti-Lock Control – Traction Control

-Specifications

-Description and Operation:

– Anti-Lock Control – Traction Control

-Removal and Installation:

– Anti-Lock Brake System (ABS) Module

– Front Wheel Speed Sensor

– Rear Wheel Speed Sensor

Anti-Lock Control – Stability Assist

-Removal and Installation:

– Yaw Rate Sensor

STEERING SYSTEM

Steering System – General Information

-Specifications

-General Procedures

-Power Steering System Filling and Bleeding

-Description and Operation:

– Steering System

Power Steering

-Specifications

-General Procedures:

– Power Steering Pressure Test – 4.0L

– Power Steering Pressure Test – 4.4L

– Power Steering Pressure Test – 2.7L Diesel

-Description and Operation:

– Power Steering

-Removal and Installation:

– Steering Gear – 4.0L (57.10.01)

– Steering Gear – 4.4L (57.10.01)

– Steering Gear – 2.7L Diesel (57.10.01)

– Power Steering Fluid Reservoir – 4.0L/4.4L

– Power Steering Fluid Reservoir – 2.7L Diesel

– Power Steering Fluid Cooler – 4.0L/4.4L

– Power Steering Fluid Cooler – 2.7L Diesel

– Power Steering Pump – 4.0L

– Power Steering Pump – 4.4L

– Power Steering Pump – 2.7L Diesel

– Steering Angle Sensor

Steering Linkage

-Specifications

-Description and Operation:

– Steering Linkage

-Removal and Installation:

– Tie -Rod End

– Steering Gear Boot

Steering Column

-Specifications

-Description and Operation:

– Steering Column

-Removal and Installation:

– Steering Column

– Steering Column Shaft

– Steering Wheel

Steering Column Switches

-Specifications

-Description and Operation:

– Steering Column Switches

-Removal and Installation:

– Steering Column Lock and Ignition Switch Housing

– Ignition Switch

– Steering Column Multifunction Switch RH

– Steering Column Multifunction Switch LH

POWERTRAIN – ENGINE

Engine System – General Information

-General Procedures:

– Bearing Inspection

– Camshaft Bearing Journal Clearance

– Camshaft Bearing Journal Diameter

– Camshaft End Play

– Camshaft Lobe Lift

– Camshaft Surface Inspection

– Connecting Rod Cleaning

– Connecting Rod Large End Bore

– Crankshaft End Play

– Crankshaft Main Bearing Journal Clearance

– Cylinder Bore Out-of-Round

– Cylinder Head Distortion

– Exhaust Manifold Cleaning and Inspection

– Piston Inspection

– Piston Pin Diameter

– Piston Pin to Bore Diameter

– Piston Ring End Gap

– Piston Ring-to-Groove Clearance

– Valve Spring Free Length

– Valve Stem Diameter

– Diagnosis and Testing

– Engine – 4.0L

– Engine – 4.4L

– Engine – 2.7L Diesel

Engine – 4.0L

-Specifications

-General Procedures:

– Engine Oil Draining and Filling (12.60.05)

– Camshaft Timing

-Description and Operation:

– Engine

-Removal:

– Engine

-Installation:

– Engine

-In Vehicle Repair:

– Camshaft RH

– Crankshaft Pulley

– Crankshaft Front Seal

– Crankshaft Rear Seal

– Cylinder Block Cradle

– Cylinder Head LH

– Cylinder Head RH

– Valve Cover LH

– Valve Cover RH

– Camshaft Roller Follower

– Engine Mount LH

– Engine Mount RH

– Flexplate

– Oil Pump

– Oil Pan

– Oil Cooler

– Engine Front Cover

– Timing Drive Components

– Camshaft Drive Cassette LH

– Camshaft Drive Cassette RH

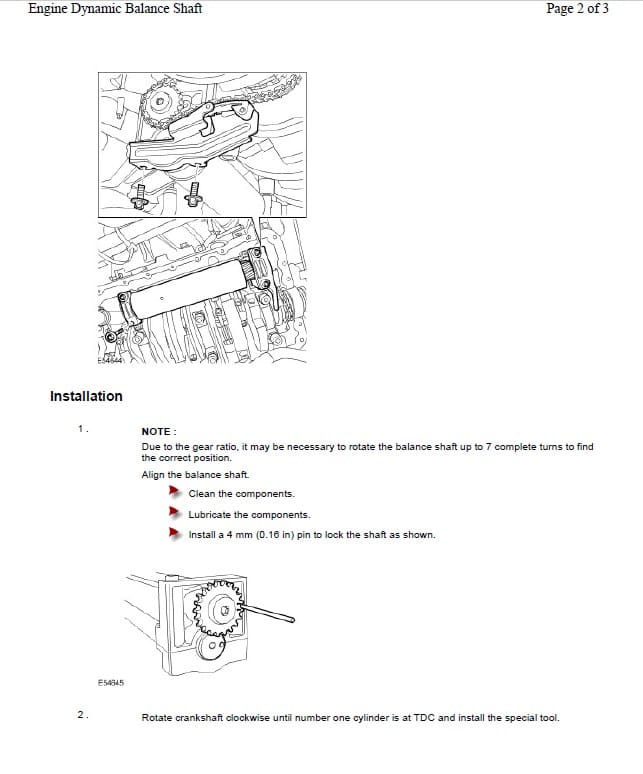

– Engine Dynamic Balance Shaft

– Jackshaft

– Hydraulic Timing Chain Tensioner LH

– Hydraulic Timing Chain Tensioner RH

– Intake Manifold

– Exhaust Manifold LH

– Exhaust Manifold RH

Engine – 4.4L

-Specifications

-General Procedures:

– Valve Clearance Check

– Valve Clearance Adjustment

– Engine Oil Draining and Filling

-Description and Operation:

– Engine

-Removal:

– Engine

-Installation:

– Engine

-In Vehicle Repair:

– Camshafts RH

– Camshafts LH

– Crankshaft Pulley

– Crankshaft Front Seal

– Crankshaft Rear Seal

– Timing Drive Components

– Cylinder Head LH

– Valve Cover LH

– Valve Cover RH

– Engine Mount LH

– Engine Mount RH

– Flexplate

– Oil Pump

– Oil Pan

– Oil Cooler

– Engine Front Cover

– Exhaust Manifold LH

– Exhaust Manifold RH

Engine – 2.7L Diesel

-Specifications

-General Procedures:

– Engine Oil Draining and Filling

-Description and Operation:

– Engine

-Removal:

– Engine – Vehicles With: Automatic Transmission

– Engine – Vehicles With: Manual Transmission

-Installation:

– Engine – Vehicles With: Automatic Transmission

– Engine – Vehicles With: Manual Transmission

-In Vehicle Repair:

– Camshaft LH

– Camshaft RH

– Camshaft Front Seal

– Camshaft Rear Seal

– Crankshaft Front Seal

– Crankshaft Rear Seal with Retainer Plate

– Cylinder Head LH

– Cylinder Head RH

– Valve Cover LH

– Valve Cover RH

– Engine Mount LH

– Engine Mount RH

– Flywheel

– Flexplate

– Oil Pump

– Oil Pressure Switch

– Oil Cooler

– Oil Pump Screen and Pickup Tube

– Oil Pan

– Timing Belt Cover

– Timing Belt

– Exhaust Manifold LH

– Exhaust Manifold RH

– Oil Filter Housing

Engine Cooling – 4.0L

-Specifications

-General Procedures:

– Cooling System Draining, Filling and Bleeding

-Description and Operation:

– Engine Cooling

-Removal and Installation:

– Coolant Expansion Tank

– Cooling Fan

– Cooling Fan Shroud

– Radiator

– Thermostat

– Coolant Pump

Engine Cooling – 4.4L

-Specifications

-General Procedures:

– Cooling System Draining, Filling and Bleeding

-Description and Operation:

– Engine Cooling

-Removal and Installation:

– Coolant Expansion Tank

– Cooling Fan

– Cooling Fan Shroud

– Radiator

– Thermostat

– Coolant Pump

Engine Cooling – 2.7L Diesel

-Specifications

-General Procedures:

– Cooling System Draining, Filling and Bleeding

-Description and Operation:

– Engine Cooling

-Removal and Installation:

– Coolant Expansion Tank

– Cooling Fan

– Cooling Fan Shroud

– Radiator

– Thermostat

– Coolant Pump

Fuel Charging and Controls – 4.0L

-Specifications

-Description and Operation:

– Fuel Charging and Controls

-Removal and Installation:

– Fuel Rail

– Throttle Body Gasket

– Fuel Injector

Fuel Charging and Controls – 4.4L

-Specifications

-Description and Operation:

– Fuel Charging and Controls

-Removal and Installation:

– Fuel Rail

– Fuel Injectors

– Intake Manifold Assembly

– Throttle Body Gasket

Fuel Charging and Controls – 2.7L Diesel

-Specifications

-Description and Operation:

– Fuel Charging and Controls

-Removal and Installation:

– Fuel Pump

– Fuel Injectors

– Intake Air Shutoff Throttle

Fuel Charging and Controls – Turbocharger – 2.7L Diesel

-Specifications

-Description and Operation:

– Turbocharger

Removal and Installation:

– Turbocharger

– Turbocharger Intake Tube

Accessory Drive – 4.0L

-Specifications

-Description and Operation:

– Accessory Drive

-Removal and Installation:

– Accessory Drive Belt

– Accessory Drive Belt Tensioner

– Accessory Drive Belt Idler Pulley

Accessory Drive – 4.4L

-Specifications

-Description and Operation:

– Accessory Drive

-Removal and Installation:

– Cooling Fan Belt

– Cooling Fan Belt Tensioner

– Accessory Drive Belt

– Accessory Drive Belt Tensioner

– Accessory Drive Belt Idler Pulley

Accessory Drive – 2.7L Diesel

-Specifications

-Description and Operation:

– Accessory Drive

-Removal and Installation:

– Fuel Injection Pump Belt

– Accessory Drive Belt

– Accessory Drive Belt Tensioner

– Accessory Drive Belt Idler Pulley

– Fuel Injection Pump Pulley

Starting System – 4.0L

-Specifications

-Description and Operation:

– Starting System

-Removal and Installation:

– Starter Motor

Starting System – 4.4L

-Specifications

-Description and Operation:

– Starting System

-Removal and Installation:

– Starter Motor

Starting System – 2.7L Diesel

-Specifications

-Description and Operation:

– Starting System

-Removal and Installation:

– Starter Motor

Engine Ignition – 4.0L

-Specifications

-Description and Operation:

– Engine Ignition

-Removal and Installation:

– Spark Plugs

– Ignition Coil

Engine Ignition – 4.4L

-Specifications

-Description and Operation:

– Engine Ignition

-Removal and Installation:

– Spark Plugs

– Ignition Coil-On-Plug

Glow Plug System

-Specifications

-Description and Operation:

– Glow Plug System

-Removal and Installation:

– Glow Plugs

– Glow Plug Module

– Glow Plug Relay

Engine Emission Control – 4.0L

-Specifications

-Description and Operation:

– Engine Emission Control

-Removal and Installation:

– Positive Crankcase Ventilation (PCV) Valve

– Exhaust Gas Recirculation (EGR) Modulator Valve

Engine Emission Control – 4.4L

-Specifications

-Description and Operation:

– Engine Emission Control

-Removal and Installation:

– Positive Crankcase Ventilation (PCV) Valve

– Exhaust Gas Recirculation (EGR) Modulator Valve

Engine Emission Control – 2.7L Diesel

-Specifications

-Description and Operation:

– Engine Emission Control

-Removal and Installation:

– Crankcase Vent Oil Separator

– Exhaust Gas Recirculation (EGR) Valve LH

– Exhaust Gas Recirculation (EGR) Valve RH

– Exhaust Gas Recirculation (EGR) Valve Outlet Tube

Intake Air Distribution and Filtering – 4.0L

-Specifications

-Description and Operation:

– Intake Air Distribution and Filtering

-Removal and Installation:

– Air Cleaner

– Air Cleaner Element

– Intake Air Resonator

Intake Air Distribution and Filtering – 4.4L

-Specifications

-Description and Operation:

– Intake Air Distribution and Filtering

-Removal and Installation:

– Air Cleaner

– Air Cleaner Element

– Intake Air Resonator

Intake Air Distribution and Filtering – 2.7L Diesel

-Specifications

-Description and Operation:

– Intake Air Distribution and Filtering

Removal and Installation:

– Air Cleaner

– Air Cleaner Element

– Charge Air Cooler

Evaporative Emissions – 4.0L

-Specifications

-General Procedures:

– Evaporative Emission System Leak Test

-Description and Operation:

– Evaporative Emissions

-Removal and Installation:

– Evaporative Emission Canister

– Evaporative Emission Canister Purge Valve

Evaporative Emissions – 4.4L

-Specifications

-General Procedures:

– Evaporative Emission System Leak Test

-Description and Operation:

– Evaporative Emissions

-Removal and Installation:

– Evaporative Emission Canister

– Evaporative Emission Canister Purge Valve

Evaporative Emissions – 2.7L Diesel

-Description and Operation

Electronic Engine Controls – 4.0L

-Specifications

-Description and Operation:

– Electronic Engine Controls

-Removal and Installation:

– Engine Oil Pressure (EOP) Sensor

– Oil Temperature Sensor

– Engine Control Module (ECM)

– Engine Coolant Temperature (ECT) Sensor

– Crankshaft Position (CKP) Sensor

– Throttle Position (TP) Sensor

– Camshaft Position (CMP) Sensor

– Knock Sensor (KS) LH

– Knock Sensor (KS) RH

– Heated Oxygen Sensor (HO2S) LH

– Mass Air Flow (MAF) Sensor

– Intake Manifold Tuning (IMT) Valve

– Catalyst Monitor Sensor LH

– Engine Control Module (ECM) Cooling Fan

Electronic Engine Controls – 4.4L

-Specifications

-Description and Operation:

– Electronic Engine Controls

-Removal and Installation:

– Variable Camshaft Timing (VCT) Oil Control Solenoid

– Engine Oil Pressure (EOP) Sensor

– Oil Temperature Sensor

– Engine Control Module (ECM)

– Engine Coolant Temperature (ECT) Sensor

– Crankshaft Position (CKP) Sensor

– Throttle Position (TP) Sensor

– Camshaft Position (CMP) Sensor

– Knock Sensor (KS)

– Manifold Absolute Pressure (MAP) Sensor

– Fuel Temperature Sensor (19.22.08)

– Heated Oxygen Sensor (HO2S) LH

– Mass Air Flow (MAF) Sensor

– Catalyst Monitor Sensor LH

– Engine Control Module (ECM) Cooling Fan

Electronic Engine Controls – 2.7L Diesel

-Specifications

-Description and Operation:

– Electronic Engine Controls

-Removal and Installation:

– Engine Oil Pressure (EOP) Sensor

– Oil Temperature Sensor

– Engine Control Module (ECM)

– Engine Coolant Temperature (ECT) Sensor

– Crankshaft Position (CKP) Sensor

– Crankshaft Position (CKP) Sensor Ring

– Camshaft Position (CMP) Sensor

– Manifold Absolute Pressure (MAP) Sensor

– Fuel Temperature Sensor

– Fuel Rail Pressure (FRP) Sensor

AUTOMATIC TRANSMISSION / TRANSAXLE

Automatic Transmission/Transaxle – 4.0L

-Specifications

-General Procedures:

– Transmission Fluid Drain and Refill

– Transmission Fluid Level Check

-Description and Operation:

– Automatic Transmission

-Removal and Installation:

– Transmission

-In Vehicle Repair:

– Selector Shaft Seal

– Transmission Control Module (TCM)

– Output Shaft Seal

– Fluid Pan, Gasket and Filter

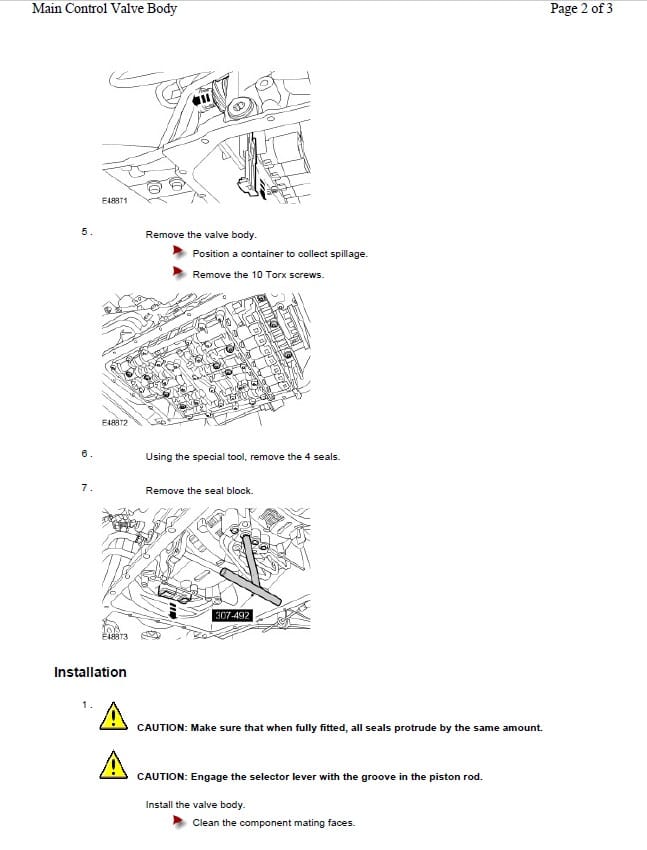

– Main Control Valve Body

– Transmission Support Insulator

Automatic Transmission/Transaxle – 4.4L

-Specifications

-General Procedures:

– Transmission Fluid Drain and Refill

– Transmission Fluid Level Check

-Description and Operation:

– Automatic Transmission

-Removal and Installation:

– Transmission

-In Vehicle Repair:

– Selector Shaft Seal

– Transmission Control Module (TCM)

– Output Shaft Seal

– Fluid Pan, Gasket and Filter

– Main Control Valve Body

– Transmission Support Insulator

Automatic Transmission/Transaxle – 2.7L Diesel

-Specifications

-General Procedures:

– Transmission Fluid Drain and Refill

– Transmission Fluid Level Check

-Description and Operation:

– Automatic Transmission

-Removal and Installation:

– Transmission

-In Vehicle Repair:

– Selector Shaft Seal

– Transmission Control Module (TCM)

– Output Shaft Seal

– Fluid Pan, Gasket and Filter

– Main Control Valve Body

– Transmission Support Insulator

Transmission/Transaxle Cooling – 4.0L

-Removal and Installation:

– Transmission Fluid Cooler – 4.0L

Transmission/Transaxle Cooling – 4.4L

-Removal and Installation:

– Transmission Fluid Cooler

Transmission/Transaxle Cooling – 2.7L Diesel

-Removal and Installation:

– Transmission Fluid Cooler

Automatic Transmission/Transaxle External Controls – 4.0L

-Specifications

-General Procedures:

– Selector Lever Cable Adjustment

-Removal and Installation:

– Selector Lever

– Selector Lever Knob

– Selector Lever Cable

– Selector Lever Gate Finish Panel

Automatic Transmission/Transaxle External Controls – 4.4L

-Specifications

-General Procedures:

– Selector Lever Cable Adjustment

-Removal and Installation:

– Selector Lever

– Selector Lever Cable

– Selector Lever Knob

– Selector Lever Gate Finish Panel

Automatic Transmission/Transaxle External Controls – 2.7L Diesel

-Specifications

-General Procedures:

– Selector Lever Cable Adjustment

-Removal and Installation:

– Selector Lever

– Selector Lever Knob

– Selector Lever Cable

– Selector Lever Gate Finish Panel

– Manual Transmission/Transaxle, Clutch and Transfer Case

Manual Transmission/Transaxle and Clutch – General Information

-Specifications

-General Procedures:

– Clutch System Bleeding

Clutch – 2.7L Diesel

-Specifications

-Description and Operation:

– Clutch

-Removal and Installation:

– Pilot Bearing

– Clutch Disc and Pressure Plate

Clutch Controls – 2.7L Diesel

-Specifications

-Description and Operation:

– Clutch Controls

-Removal and Installation:

– Clutch Master Cylinder

– Clutch Pedal

– Clutch Slave Cylinder

Manual Transmission/Transaxle – 2.7L Diesel

-Specifications

-General Procedures:

– Transmission Draining and Filling

-Description and Operation:

– Manual Transmission

-Removal:

– Transmission

-Installation:

– Transmission

-In Vehicle Repair:

– Output Shaft Speed (OSS) Sensor

– Output Shaft Seal

– Countershaft Seal

– Input Shaft Seal

– Gearshift Control Shaft Seal

– Gear Position Sensor

Manual Transmission/Transaxle External Controls – 2.7L Diesel

-Specifications

-Description and Operation:

– External Controls

-Removal and Installation:

– Gearshift Lever

Four-Wheel Drive Systems

-Specifications

-Description and Operation:

– Four -Wheel Drive Systems

– Four -Wheel Drive Systems

-Removal and Installation:

– Four -Wheel Drive (4WD) Control Module

– Transfer Case Shift Motor

– Transfer Case Clutch Solenoid

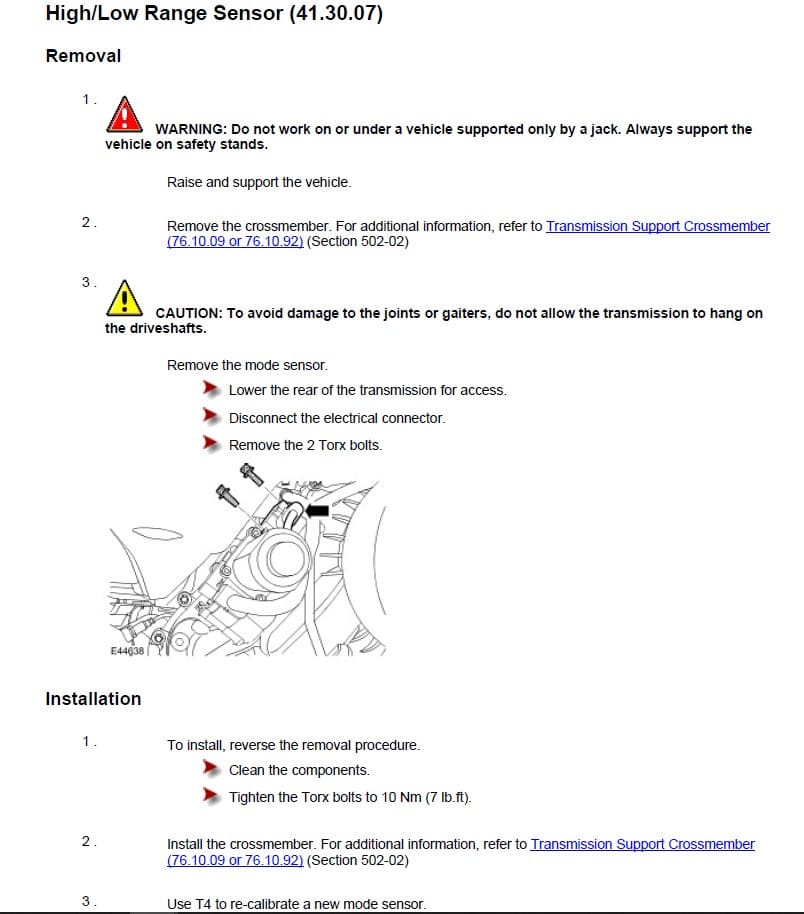

– High/Low Range Sensor

Transfer Case

-Specifications

-General Procedures:

– Transfer Case Draining and Filling

-Description and Operation:

– Transfer Case

-Removal:

– Transfer Case – 4.4L

– Transfer Case – 2.7L Diesel

– Transfer Case – 4.0L

-Installation:

– Transfer Case – 4.0L

– Transfer Case – 4.4L

– Transfer Case – 2.7L Diesel

-In Vehicle Repair:

– Transfer Case Input Shaft Seal – 4.0L

– Transfer Case Input Shaft Seal – 4.4L

– Transfer Case Input Shaft Seal – 2.7L Diesel

– Transfer Case Front Output Shaft Seal

– Transfer Case Rear Output Shaft Seal

EXHAUST SYSTEM

Exhaust System – 4.0L

-Specifications

-Description and Operation:

– Exhaust System

-Removal and Installation:

– Catalytic Converter LH

– Catalytic Converter RH

– Exhaust System

– Muffler

– Tailpipe

Exhaust System – 4.4L

-Specifications

-Description and Operation:

– Exhaust System

-Removal and Installation:

– Catalytic Converter LH

– Catalytic Converter RH

– Exhaust System

– Muffler

– Tailpipe

FUEL SYSTEM

Fuel System – General Information

-General Procedures:

– Low-Pressure Fuel System Bleeding

– Fuel Tank Draining

– Fuel System Pressure Release – 4.0L

– Fuel System Pressure Release – 4.4L

Fuel Tank and Lines – 4.0L

-Specifications

-Description and Operation:

– Fuel Tank and Lines

-Removal and Installation:

– Fuel Pump Module

– Fuel Tank Filler Pipe

– Fuel Tank

Fuel Tank and Lines – 4.4L

-Specifications

-Description and Operation:

– Fuel Tank and Lines

-Removal and Installation:

– Fuel Pump Module

– Fuel Tank Filler Pipe

– Fuel Tank

Acceleration Control – 4.0L

-Specifications

-Description and Operation:

– Acceleration Control

-Removal and Installation:

– Accelerator Pedal

Acceleration Control – 4.4L

-Specifications

-Description and Operation:

– Acceleration Control

-Removal and Installation:

– Accelerator Pedal

Speed Control

-Description and Operation:

– Speed Control

CLIMATE CONTROL SYSTEM

Climate Control System – General Information

-Specifications

-General Procedures:

– Air Conditioning (A/C) System Recovery, Evacuation and Charging

Air Distribution and Filtering

-Description and Operation:

– Air Distribution and Filtering

-Removal and Installation:

– Driver Side Register Trim Panel

– Passenger Side Register Trim Panel

– Pollen Filter

– Plenum Chamber

Heating and Ventilation

-Description and Operation:

– Heating and Ventilation

-Removal and Installation:

– Blower Motor

– Heater Core – LHD

– Heater Core – RHD

Auxiliary Heating

-Specifications

-Description and Operation:

– Auxiliary Heater

-Removal and Installation:

– Fuel Fired Booster Heater

Air Conditioning – 4.0L

-Specifications

-Description and Operation:

– Air Conditioning

-Removal and Installation:

– Air Conditioning (A/C) Compressor

– Condenser Core

– Receiver Drier

– Air Conditioning (A/C) Pressure Transducer

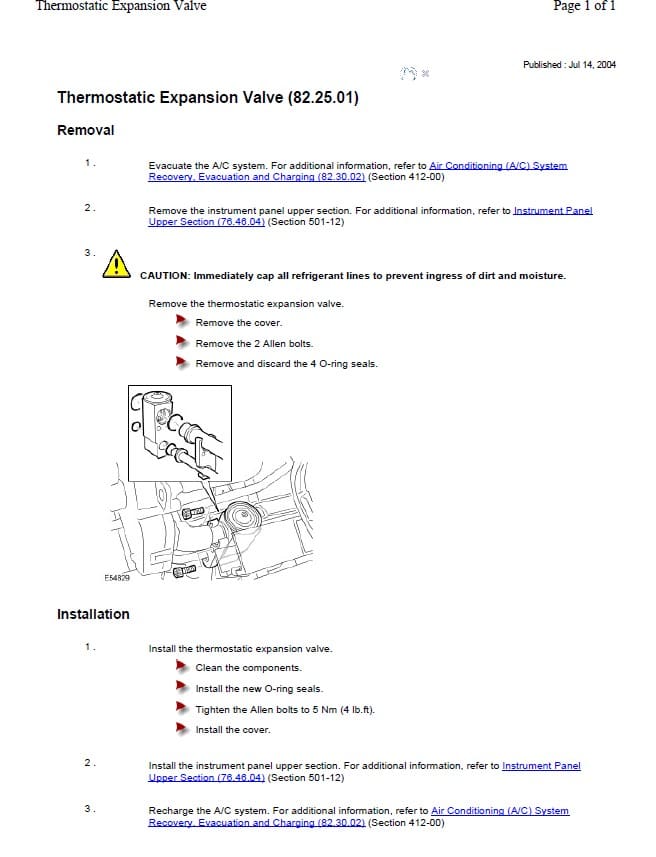

– Thermostatic Expansion Valve

– Evaporator Core

Air Conditioning – 4.4L

-Specifications

-Description and Operation:

– Air Conditioning

-Removal and Installation:

– Air Conditioning (A/C) Compressor

– Condenser Core

– Receiver Drier

– Air Conditioning (A/C) Pressure Transducer

– Thermostatic Expansion Valve

– Evaporator Core

Auxiliary Climate Control

-Specifications

-Description and Operation:

– Auxiliary Climate Control

-Removal and Installation:

– Thermostatic Expansion Valve

– Heater Core

– Evaporator Core

– Auxiliary Climate Control Assembly

– Blower Motor

– Auxiliary Temperature Blend Door Actuator

– Auxiliary Blend Door Actuator

– Auxiliary Blower Motor Control Module

Control Components

-Specifications

-Description and Operation:

– Control Components

-Removal and Installation:

– Climate Control Assembly (80.10.02)

– Defrost Vent/Register Blend Door Actuator – LHD

– Defrost Vent/Register Blend Door Actuator – RHD

– Driver Side Temperature Blend Door Actuator

– Passenger Side Temperature Blend Door Actuator

– Instrument Panel Blend Door Actuator – LHD

– Instrument Panel Blend Door Actuator – RHD

– Sunload Sensor

-In-Vehicle :

– Temperature Sensor

– Ambient Air Temperature Sensor

– Instrumentation and Warning Systems

ELECTRICAL

Instrument Cluster and Panel Illumination

-Description and Operation:

– Instrument Cluster and Panel Illumination

Instrument Cluster

-Specifications

-Description and Operation:

– Instrument Cluster

-Removal and Installation:

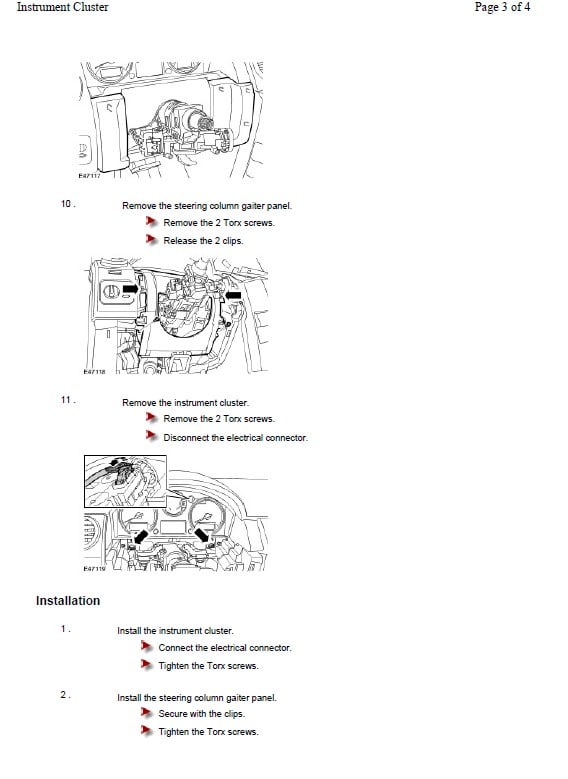

– Instrument Cluster

Horn

-Description and Operation:

-Removal and Installation

Clock

-Description and Operation

Information and Message Center

-Description and Operation

-Information and Message Center

Warning Devices

-Specifications

-Removal and Installation:

– Low Tire Pressure Module

Engine Protection System

-Specifications

Parking Aid

-Specifications

-Description and Operation:

– Parking Aid

-Removal and Installation:

– Parking Aid Module

– Parking Aid Speaker

– Front Inner Parking Aid Sensor

– Front Outer Parking Aid Sensor

– Rear Inner Parking Aid Sensor

– Rear Outer Parking Aid Sensor

– Battery and Charging System

Charging System – General Information

-Specifications

Battery, Mounting and Cables

-Specifications

-Description and Operation:

– Battery and Cables

-Removal and Installation:

– Battery Tray

– Auxiliary Battery Tray

– Battery

Generator and Regulator – 4.0L

-Specifications

-Description and Operation:

– Generator

-Removal and Installation:

– Generator

Generator and Regulator – 4.4L

-Specifications

-Description and Operation:

– Generator

-Removal and Installation:

– Generator

ENTERTAINMENT SYSTEM

Audio Unit

-Specifications

-Description and Operation:

– Audio System

-Removal and Installation:

– Audio Unit

– Audio Amplifier

Antenna

-Description and Operation:

– Antenna

-Removal and Installation

Speakers

-Specifications

-Description and Operation:

– Speakers

-Removal and Installation:

– Front Door Speaker

– Rear Door Speaker

– Instrument Panel Speaker

– Quarter Panel Speaker

– Tailgate Speaker

Video System

-Description and Operation:

– Video System

LIGHTING

Exterior Lighting

-Specifications

-General Procedures:

– Headlamp Adjustment

-Description and Operation:

– Exterior Lighting

-Removal and Installation:

– Stoplamp Switch

– Headlamp Assembly

– Side Turn Signal Lamp

– Rear Lamp Assembly

– Front Fog Lamp

– High Mounted Stoplamp

– Adaptive Front Lighting Module

– Headlamp Switch

Interior Lighting

-Specifications

-Description and Operation

– Interior Lighting

Daytime Running Lamps (DRL)

-Description and Operation:

– Daytime Running Lamps (DRL)

– Electrical Distribution

Module Communications Network

– Specifications

-Description and Operation:

– Communications Network

-Removal and Installation:

– Battery Junction Box (BJB) – 4.0L

– Battery Junction Box (BJB) – 4.4L

– Battery Junction Box (BJB) – 2.7L Diesel

– Central Junction Box (CJB)

Wiring Harnesses

– Specifications

-Removal and Installation:

– Engine Wiring Harness – 4.0L

– Engine Wiring Harness – 4.4L

– Engine Wiring Harness – 2.7L Diesel

– Liftgate Wiring Harness

– Electronic Feature Group

Anti-Theft – Active

-Specifications

-Description and Operation:

– Anti-Theft – Active

-Removal and Installation:

– Hood Switch

– Antenna

Anti-Theft – Passive

-Description and Operation:

– Anti-Theft – Passive

Navigation System

-Description and Operation:

– Navigation System

-Removal and Installation:

– Navigation System Display Module

– Navigation System Compact Disc (CD) Unit

– Navigation System Traffic Amplifier

– Navigation System Antenna – Vehicles With: Metal Roof Panel

– Navigation System Antenna – Vehicles With: Glass Roof Panel

Cellular Phone

-Specifications

-Description and Operation:

– Cellular Phone

-Removal and Installation:

– Cellular Phone Antenna

BODY

Front End Body Panels

-Specifications

-Description and Operation

-Removal and Installation:

– Fender

– Fender Splash Shield

– Engine Undershield

Body Closures

-General Procedures:

– Liftgate Alignment

-Description and Operation

-Removal and Installation:

– Fuel Filler Door Assembly

– Fuel Filler Interlock Catch

– Liftgate

Interior Trim and Ornamentation

-Specifications

-Description and Operation

-Removal and Installation:

– Engine Cover – 4.0L

– Engine Cover – 4.4L

– Engine Cover – 2.7L Diesel

– A-Pillar Trim Panel

– Cowl Side Trim Panel

– B-Pillar Upper Trim Panel

– B-Pillar Lower Trim Panel

– D-Pillar Trim Panel

– C-Pillar Lower Trim Panel

– C-Pillar Upper Trim Panel

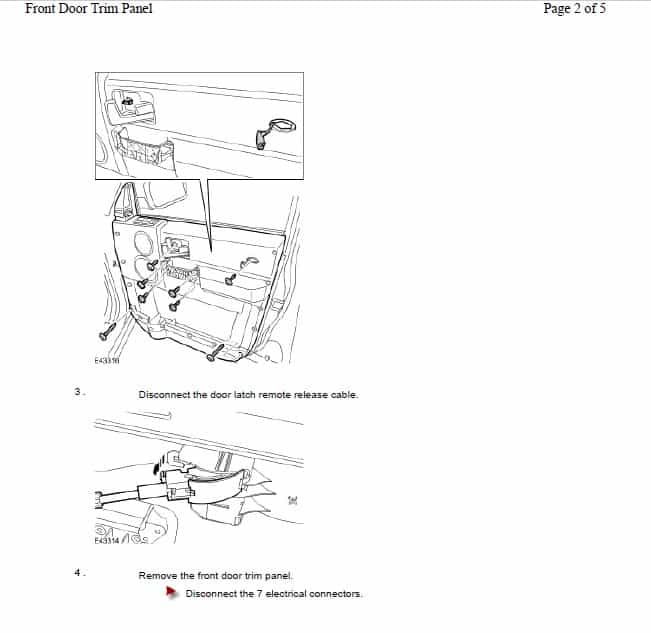

– Front Door Trim Panel

– Rear Door Trim Panel

– Liftgate Trim Panel

– Tailgate Trim Panel

– Scuff Plate Trim Panel

– Headliner

Exterior Trim and Ornamentation

-Description and Operation

-Removal and Installation:

– A-Pillar Moulding LH

– Fender Moulding

– Rear Quarter Panel Moulding

– Radiator Grille

– Rear Quarter Window Moulding

Rear View Mirrors

-Specifications

-Description and Operation:

– Rear View Mirrors

-Removal and Installation:

– Interior Mirror

– Exterior Mirror Glass

– Exterior Mirror

Seating

-Specifications

-Description and Operation:

– Seats

-Removal and Installation:

– Front Seat Cushion (78.10.12/99)

– Front Seat (78.10.44/99)

– Third Row Seat (78.10.39)

– Rear Seat – Vehicles With: 60/40 Split Seat

– Rear Seat – Vehicles With: 40/20/40 Split Seat

– Front Seat Cushion Cover

– Front Seat Cushion Heater Mat

– Third Row Seat Cushion Cover

– Third Row Seat Cushion

– Rear Seat Cushion Cover – Vehicles With: 60/40 Split Seat

– Rear Seat Cushion Cover – Vehicles With: 40/20/40 Split Seat

– Front Seat Track Motor

– Front Seat Height Adjustment Motor

– Front Seat Tilt Motor

– Front Seat Recliner Motor

– Front Seat Control Switch

– Front Seat Backrest Cover

– Third Row Seat Backrest Cover

– Front Seat Backrest Heater Mat

– Rear Seat Backrest Cover – Vehicles With: 60/40 Split Seat

– Rear Seat Backrest Cover – Vehicles With: 40/20/40 Split Seat

Glass, Frames and Mechanisms

-Specifications

-Description and Operation:

– Glass, Frames and Mechanisms

-Removal and Installation:

– Front Door Window Glass

– Rear Door Window Glass

– Liftgate Window Glass

– Rear Door Fixed Window Glass

– Windshield Glass

– Glass Roof Panel

– Rear Quarter Window Glass

– Front Door Window Regulator and Motor

– Rear Door Window Regulator and Motor

– Front Door Window Control Switch

– Rear Door Window Control Switch

Instrument Panel and Console

-Specifications

-Description and Operation:

– Instrument Panel

– Floor Console

– Overhead Console

-Removal and Installation:

– Floor Console

– Instrument Panel Console

– Floor Console Upper Panel

– Instrument Panel Upper Section

– Instrument Panel – 4.4L

– Instrument Panel – 2.7L Diesel

– Instrument Panel – 4.0L

– Instrument Panel Driver Side Reinforcement

– Instrument Panel Passenger Side Reinforcement

– Instrument Panel Center Reinforcement

– Glove Compartment

– Instrument Panel Console Switch Assembly

Handles, Locks, Latches and Entry Systems

-Specifications

-General Procedures:

– Tailgate Striker Adjustment

– Liftgate Striker Adjustment

-Description and Operation:

– Handles, Locks, Latches and Entry Systems

-Removal and Installation:

– Ignition Lock Cylinder

– Hood Latch Release Handle

– Front Door Latch

– Rear Door Latch

– Liftgate Latch

– Door Lock Cylinder

– Tailgate Latch

– Exterior Front Door Handle

– Exterior Rear Door Handle

– Liftgate Latch Actuator

Wipers and Washers

-Specifications

-Description and Operation:

– Wipers and Washers

-Removal and Installation:

– Windshield Washer Reservoir

– Windshield Washer Pump

– Rain Sensor

– Front Wiper Pivot Arm

– Windshield Wiper Motor

– Headlamp Washer Jet

– Headlamp Washer Pump

– Rear Wiper Pivot Arm

– Rear Window Wiper Motor

Roof Opening Panel

-Specifications

-General Procedures:

– Roof Opening Panel Alignment

-Description and Operation:

– Roof Opening Panel

-Removal and Installation:

– Roof Opening Panel

– Roof Opening Panel Glass

– Roof Opening Panel Motor

– Roof Opening Panel Module

Bumpers

-Specifications

-Description and Operation

-Removal and Installation:

– Front Bumper

– Front Bumper Cover

– Rear Bumper Cover

Safety Belt System

-Specifications

-Description and Operation:

– Safety Belt System

-Removal and Installation:

– Front Safety Belt Retractor

– Second Row Center Safety Belt Retractor – Vehicles With: 60/40 Split Seat

– Second Row Center Safety Belt Retractor – Vehicles With: 40/20/40 Split Seat

– Second Row Safety Belt Retractor

– Third Row Safety Belt Retractor

– Front Safety Belt Buckle

– Rear Safety Belt Buckle – Vehicles With: 40/20/40 Split Seat

– Rear Safety Belt Buckle LH – Vehicles With: 60/40 Split Seat

– Rear Safety Belt Buckle RH – Vehicles With: 60/40 Split Seat

– Rear Center Safety Belt Buckle – Vehicles With: 60/40 Split Seat

Supplemental Restraint System

-Specifications

-Description and Operation:

– Air Bag and Safety Belt Pretensioner Supplemental Restraint System (SRS)

-Removal and Installation:

– Driver Air Bag Module

– Passenger Air Bag Module

– Rear Side Air Curtain Module

– Front Impact Severity Sensor

– Passenger Air Bag Deactivation (PAD) Switch

– Clockspring

– B-Pillar Side Impact Sensor

– C-Pillar Side Impact Sensor

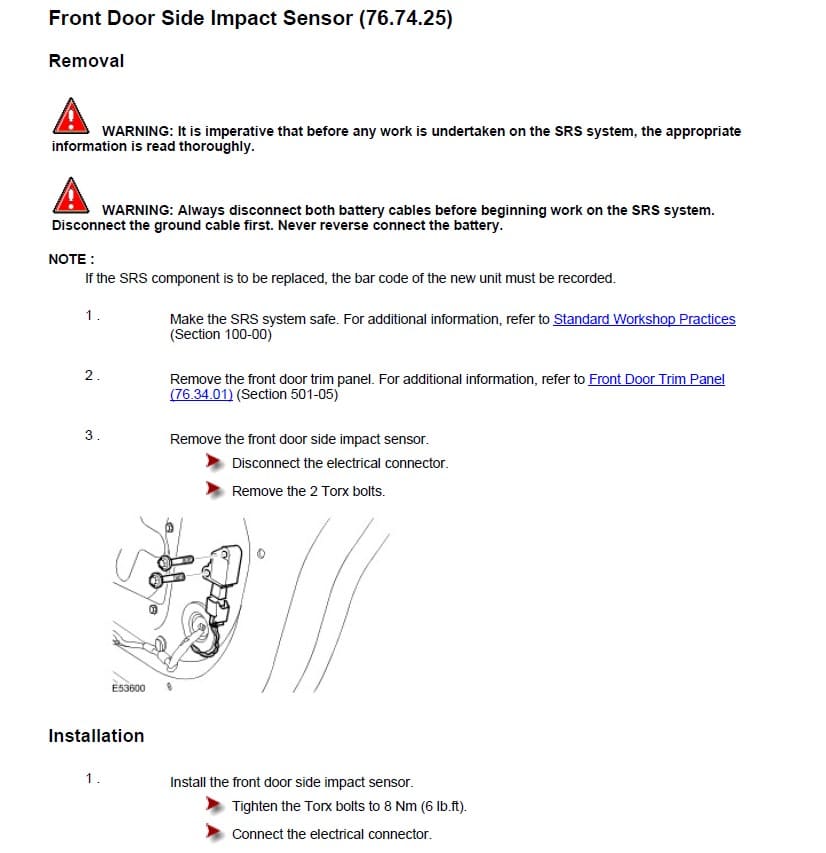

– Front Door Side Impact Sensor

– Side Air Bag Module

– Side Air Curtain Module

– Restraints Control Module (RCM)

– Occupant Classification Sensor

BODY REPAIR

Body Repairs – General Information

-Description and Operation:

Body Repairs – Corrosion Protection

-Description and Operation

Body Repairs – Water Leaks

-Description and Operation

Body Repairs – Vehicle Specific Information and Tolerance Checks

-Description and Operation:

– Body and Frame

Front End Sheet Metal Repairs

-Specifications

-Description and Operation:

– Front End Sheet Metal

-Removal and Installation:

– Hood Latch Panel

– Front Crossmember

– Front Side Member

– Front Side Member Section

– Fender Apron Panel Reinforcement

– Fender Apron Panel

– Fender Apron Panel Section

– Front Wheelhouse

– Front Wheelhouse Reinforcement

– Front Wheelhouse Section

– Fender Apron Panel Closing Panel

– Fender Apron Panel Reinforcement Front Section

– Fender Apron Panel Reinforcement Rear Section

Roof Sheet Metal Repairs

-Specifications

-Description and Operation:

– Roof

-Removal and Installation:

– Roof Panel

– Roof Front Frame

Side Panel Sheet Metal Repairs

-Specifications

-Description and Operation:

– Side Panel Sheet Metal

-Removal and Installation:

– Rocker Panel

– A-Pillar Outer Panel

– Side Panel

– B-Pillar Outer Panel

– A-Pillar Reinforcement

– B-Pillar Reinforcement

– Side Panel Front Section

Rear End Sheet Metal Repairs

-Specifications

-Description and Operation:

– Rear End Sheet Metal

-Removal and Installation:

– Quarter Panel

– Inner Quarter Panel

– Water Drain Panel

– Rear Wheelhouse Outer

– Rear Lamp Mounting Panel

– Back Panel

– Rear Floor Panel Section

– Rear Crossmember

– Rear Side Member

– Quarter/Side Panel Rear Section LH

– Rear Side Member Section

– D-Pillar Inner Lower Panel

– D-Pillar Closing Panel

– Frame and Mounting

Full Frame and Body Mounting

-Specifications

-General Procedures:

– Welding Precautions

-Description and Operation:

– Frame and Body Mounting

-Removal and Installation:

– Transmission Support Crossmember

– Body

– Rear Crossmember

Others

-Overwiew

-LR3 Scheduled maintenance times

-LR3 sevice Times

Service Bulletin

-DVD sound quality

-A pillar water leak

-EAS Connector Water ingress

-park brake lamp illuminated

-PDC intermittant operation

-DVD audio fault

-infotainment diag

-Head lamp condensation

-INOP Nav.

-Door casing material removal

-Tailgate operation

-Hood adjustment

-Driving Lamp kit Programming

-DVD kit

-PTI

-Scheduled maintenance times

-Visibility from side mirror

-NAV BOOTLOADER FAULT

-tank recall

-Black box policy

-door speakers inop

-EAS messages

-2nd Row seat straps_2

Avaliações

Não há avaliações ainda.