Content:

3-cyl. injection engine (1.0 l engine, 4V, EA 211 EVO) DFN A, DFN B, DSG B, DSG D, DSG C

Technical data

Safety information:

1.1 Safety regulations for working on fuel supply

1.2 Safety measures when working on vehicles with a start/stop system

1.3 Safety precautions when using testers and measuring instruments during a road test

1.4 Safety precautions when working on the cooling system

1.5 Safety precautions when working on ignition system

Identification:

2.1 Engine number/engine data

Repair instructions:

3.1 Rules for cleanliness

3.2 General information

3.3 General repair instructions

3.4 Foreign objects in engine

3.5 Contact corrosion

3.6 Routing and attachment of lines

3.7 Fitting radiator and condensers

3.8 Checking vacuum system

Removing and installing engine:

1 Removing and installing engine

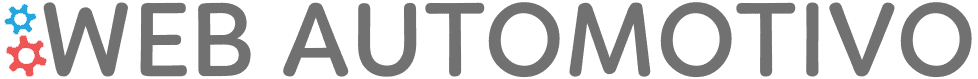

1.1 Removing motor

1.2 Separating engine and gearbox

1.3 Securing engine on engine and gearbox support

1.4 Installing engine

Assembly mountings:

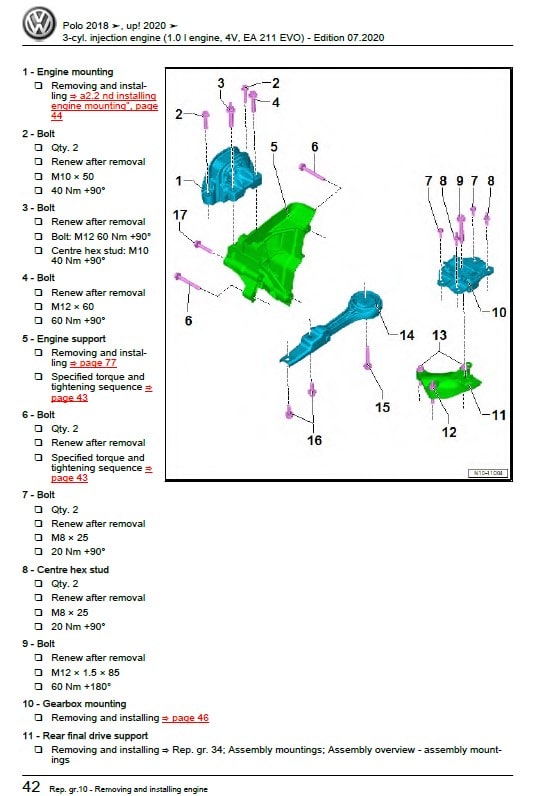

2.1 Assembly overview – assembly mountings

2.2 Removing and installing engine mounting

2.3 Removing and installing gearbox mountings

2.4 Removing and installing pendulum support

2.5 Supporting engine in installation position

2.6 Adjusting assembly mountings

2.7 Checking adjustment of assembly mountings (engine and gearbox mountings)

Crankshaft group:

1 Cylinder block (pulley end)

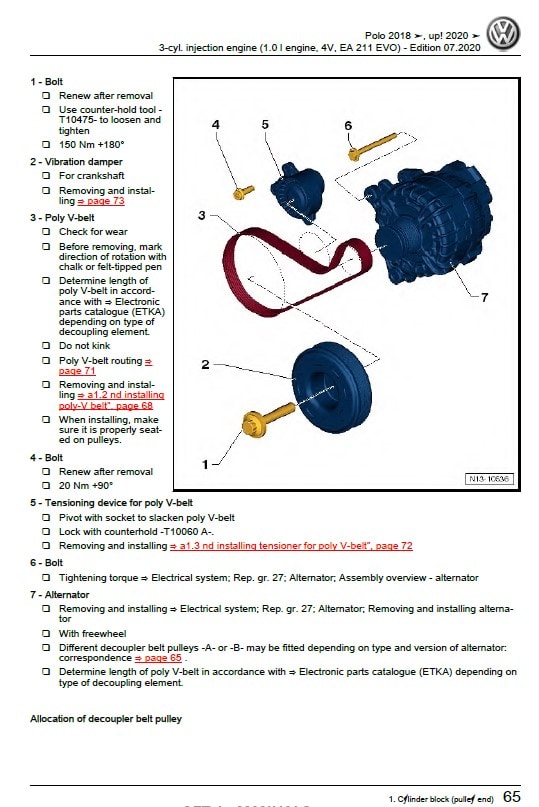

1.1 Assembly overview – poly V-belt drive

1.2 Removing and installing poly-V belt

1.3 Removing and installing tensioner for poly V-belt

1.4 Removing and installing vibration damper

1.5 Removing and installing engine support

1.6 Renewing crankshaft oil seal – belt pulley end

1.7 Removing and installing sealing flange on pulley end

2 Cylinder block, gearbox end

2.1 Assembly overview – cylinder block, gearbox end

2.2 Removing and installing flywheel

2.3 Removing and installing sealing flange on gearbox side

3 Crankshaft

3.1 Crankshaft dimensions

4 Pistons and conrods

4.1 Assembly overview – pistons and conrods

4.2 Checking pistons and

4.3 cylinder bores

4.4 Removing and installing oil spray jets

4.5 Setting piston to TDC position

Cylinder head, valve gear:

1 Cylinder head

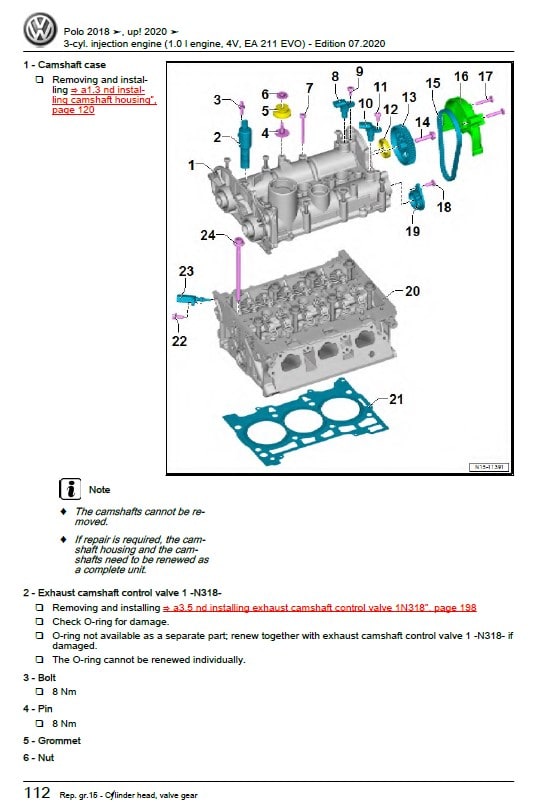

1.1 Assembly overview – cylinder head

1.2 Removing and installing cylinder head

1.3 Removing and installing camshaft housing

1.4 Checking compression

2 Toothed belt drive

2.1 Assembly overview – toothed belt cover

2.2 Assembly overview – toothed belt

2.3 Removing and installing toothed belt guard

2.4 Removing and installing toothed belt

2.5 Preassembling and installing valve timing tool

2.6 Checking valve timing

2.7 Adjusting valve timing

2.8 Removing toothed belt from camshaft

3 Valve gear

3.1 Assembly overview – valve gear

3.2 Removing and installing camshaft oil seal

3.3 Removing and installing camshaft adjuster

3.4 Removing and installing camshaft control valve 1 N727

3.5 Removing and installing exhaust camshaft control valve 1 N318

3.6 Removing and installing valve stem seals

3.7 Removing and installing holder for oil seal

4 Inlet and exhaust valves

4.1 Checking valve guides

Lubrication:

1 Sump, oil pump

1.1 Assembly overview – sump/oil pump

1.2 Engine oil

1.3 Removing and installing oil sump

1.4 Removing and installing oil pump

1.5 Removing and installing oil level and oil temperature sender G266

2 Crankcase ventilation

2.1 Assembly overview – crankcase breather system

2.2 Removing and installing oil separator

3 Oil filter, oil pressure switch

3.1 Assembly overview – oil pressure switches/oil pressure control

3.2 Removing and installing oil pressure sender G10

3.3 Checking oil pressure and oil pressure switch

3.4 Removing and installing oil filter housing

3.5 Removing and installing oil pressure regulating valve N428

Cooling:

1 Cooling system/coolant

1.1 Connection diagram – coolant hoses

1.2 Checking cooling system for leaks

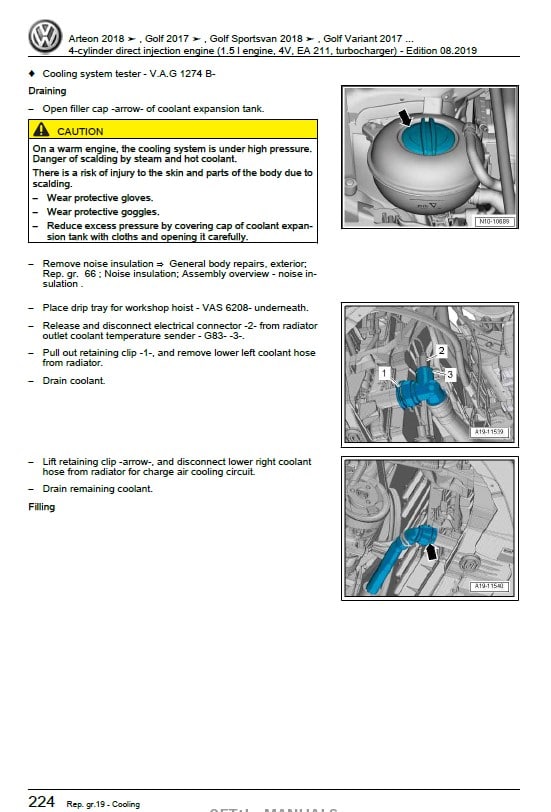

1.3 Draining and adding coolant

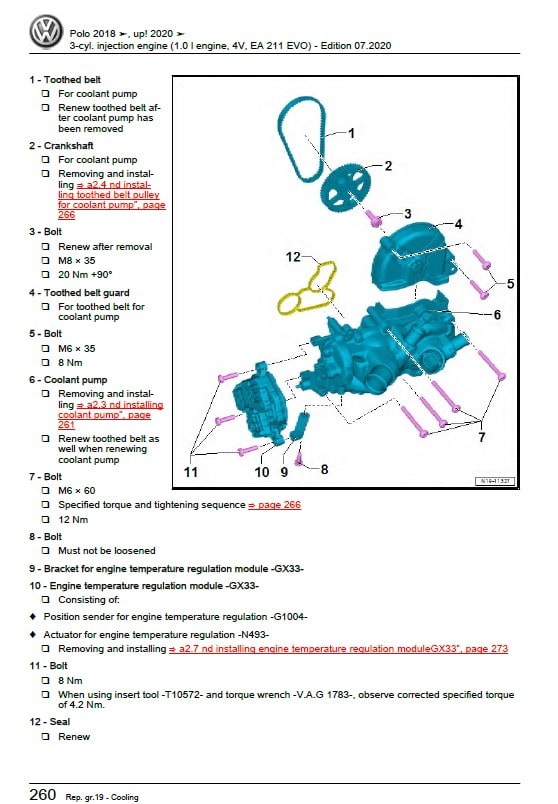

2 Coolant pump, regulation of cooling system

2.1 Assembly overview – coolant pump, thermostat

2.2 Assembly overview – coolant temperature sender

2.3 Removing and installing coolant pump

2.4 Removing and installing toothed belt pulley for coolant pump

2.5 Removing and installing coolant temperature sender G62

2.6 Removing and installing engine outlet coolant temperature sender G82

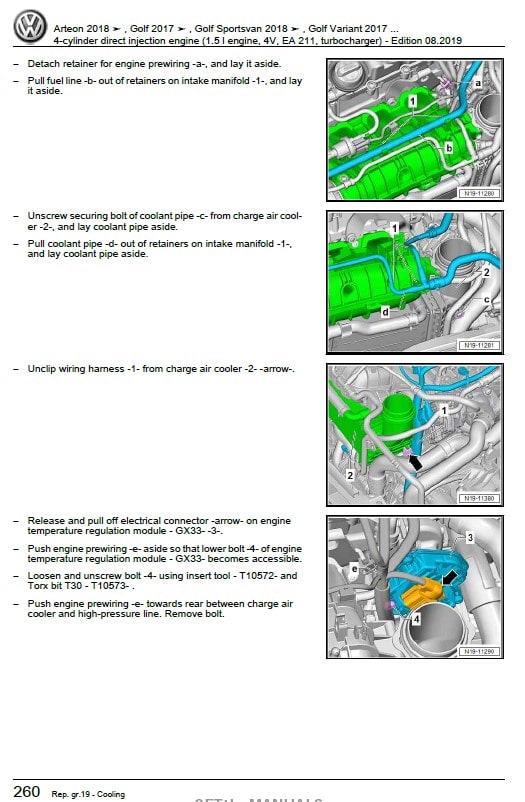

2.7 Removing and installing engine temperature regulation module GX33

2.8 Checking coolant pump

3 Coolant pipes

3.1 Assembly overview – coolant pipes

3.2 Removing and installing coolant pipes

4 Radiator, radiator fan

4.1 Assembly overview – radiator/radiator fan

4.2 Assembly overview – radiator cowl and radiator fan

4.3 Removing and installing radiator

4.4 Removing and installing radiator cowl with radiator fan

4.5 Removing and installing radiator fan VX57

Mixture preparation – injection:

1 Injection system

1.1 Overview of fitting locations – injection system

2 Injectors

2.1 Assembly overview – fuel rail with injectors

2.2 Removing and installing injectors

2.3 Checking injectors

3 Air filter

3.1 Assembly overview – air filter housing

3.2 Removing and installing air filter housing

3.3 Removing and installing resonator for intake air

3.4 Removing air duct on lock carrier

4 Intake manifold

4.1 Assembly overview – intake manifold

4.2 Removing and installing intake manifold

4.3 Removing and installing throttle valve module GX3

4.4 Cleaning throttle valve module GX3

5 Senders and sensors

5.1 Removing and installing intake manifold sender GX9

5.2 Removing and installing fuel pressure sender for low-pressure G410

6 Engine control unit

6.1 Assembly overview – engine control unit

6.2 Removing and installing engine control unit J623

6.3 Removing and installing engine (motor) control unit J623 with protective housing

7 Lambda probe

7.1 Assembly overview – Lambda probe

7.2 Removing and installing Lambda probe

Exhaust system:

1 Exhaust pipes and silencers

1.1 Assembly overview – silencers

1.2 Separating exhaust pipes from silencers

1.3 Removing and installing silencer

1.4 Aligning exhaust system free of stress

1.5 Checking exhaust system for leaks

1.6 Installation position of clamp

2 Emission control

2.1 Assembly overview – emission control

Ignition system:

1 Ignition system

1.1 Assembly overview – ignition system

1.2 Removing and installing ignition coils with output stage

1.3 Removing and installing knock sensor 1 G61

1.4 Removing and installing engine speed sender G28

1.5 Removing and installing inlet camshaft position sender G1002

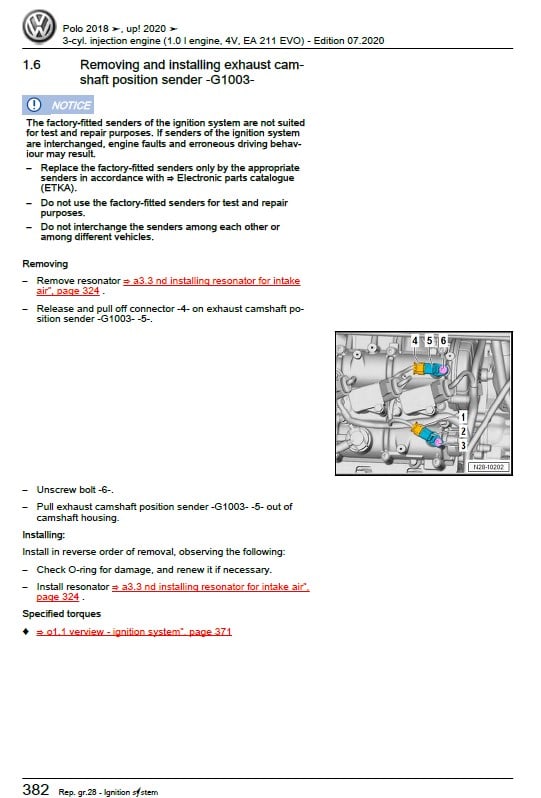

1.6 Removing and installing exhaust camshaft position sender G1003

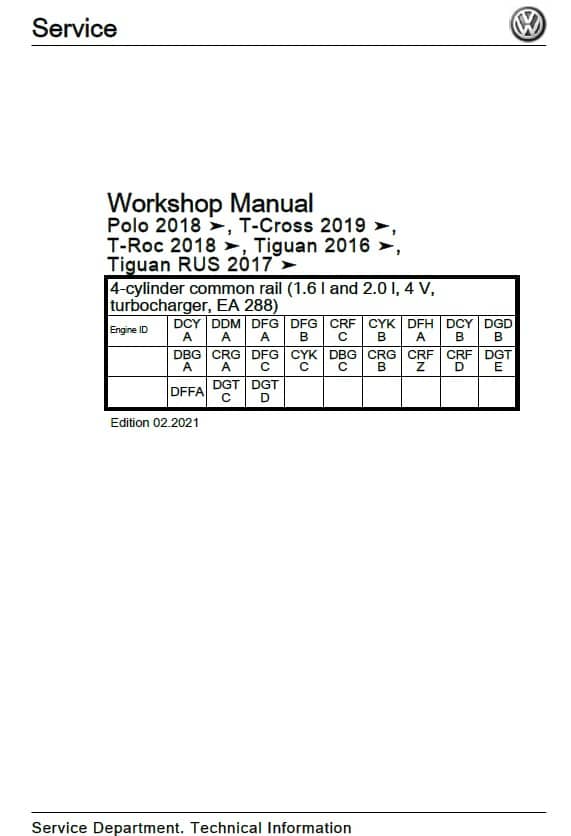

4-cylinder common rail (1.6 l and 2.0 l, 4 V, turbocharger, EA 288) – Engine ID: DCY A, DDM A, DFG A, DFG B, CRF C, CYK B, DFH A, DCY B, DGD B, DBG A, CRG A, DFG C, CYK C, DBG C, CRG B, CRF Z, CRF D, DGT E, DFFA, DGT C, DGT D – 737

Technical data:

1 Safety information

1.1 Safety regulations for working on fuel supply

1.2 Safety measures when working on vehicles with a start/stop system

1.3 Safety precautions when using testers and measuring instruments during a road test

1.4 Safety precautions when working on the cooling system

1.5 Safety precautions when working on the SCR system

1.6 Safety precautions when working on exhaust system

2 Identification

2.1 Engine number/engine data

3 Repair instructions

3.1 Rules for cleanliness

3.2 Foreign objects in engine

3.3 Contact corrosion

3.4 Routing and attachment of lines

3.5 Fitting radiator and condensers

4 Technical data

4.1 Coolant

Removing and installing engine:

1 Removing and installing engine

1.1 Removing engine

1.2 Separating engine and gearbox

1.3 Securing engine on engine and gearbox support

1.4 Installing engine

2 Assembly mountings

2.1 Assembly overview – assembly mountings

2.2 Removing and installing engine mounting

2.3 Removing and installing gearbox mounting

2.4 Removing and installing pendulum support

2.5 Supporting engine in installation position

2.6 Adjusting assembly mountings

2.7 Checking adjustment of assembly mountings

3 Engine cover panel

3.1 Removing and installing engine cover

Crankshaft group:

1 Cylinder block (pulley end)

1.1 Assembly overview – cylinder block (pulley end)

1.2 Assembly overview – sealing flange, belt pulley end

1.3 Removing and installing poly-V belt

1.4 Removing and installing tensioner for poly V-belt

1.5 Removing and installing vibration damper

1.6 Removing and installing bracket for ancillaries

1.7 Removing and installing engine support

1.8 Removing and installing sealing flange on pulley end

1.9 Renewing caps in cylinder block (pulley end)

2 Cylinder block, gearbox end

2.1 Assembly overview – cylinder block, gearbox end

2.2 Removing and installing flywheel

2.3 Removing and installing sealing flange on gearbox side

2.4 Renewing caps in cylinder block (gearbox end)

Crankshaft:

3.1 Assembly overview – crankshaft

3.2 Crankshaft dimensions

3.3 Measuring axial clearance of crankshaft

3.4 Renewing needle bearing in crankshaft

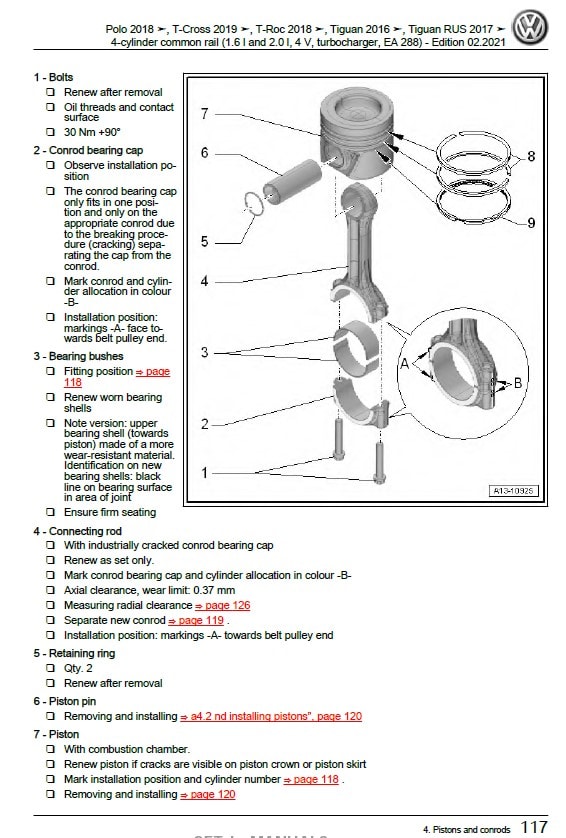

4 Pistons and conrods

4.1 Assembly overview – pistons and conrods

4.2 Removing and installing pistons

4.3 Measuring piston projection at TDC

4.4 Checking pistons and cylinder bores

4.5 Checking radial clearance of conrods

Cylinder head, valve gear:

1 Cylinder head

1.1 Assembly overview – cylinder head

1.2 Assembly overview – cylinder head cover

1.3 Removing and installing cylinder head

1.4 Removing and installing cylinder head cover

1.5 Removing and installing injector seals

1.6 Removing and installing camshaft housing

1.7 Checking compression

2 Toothed belt drive

2.1 Assembly overview – toothed belt cover

2.2 Assembly overview – toothed belt

2.3 Removing and installing toothed belt guard

2.4 Removing and installing toothed belt

2.5 Removing toothed belt from camshaft

Valve gear:

3.1 Assembly overview – valve gear

3.2 Measuring axial play of camshaft

3.3 Removing and installing camshaft oil seal

3.4 Removing and installing camshaft adjuster

3.5 Removing and installing camshaft control valve 1 N205

3.6 Checking hydraulic compensation elements

3.7 Removing and installing valve stem seals

3.8 Removing and installing control valve for the camshaft adjuster

Inlet and exhaust valves:

4.1 Checking valve guides

4.2 Checking valves

4.3 Valve dimensions

Lubrication:

1 Sump, oil pump

1.1 Assembly overview – sump/oil pump

1.2 Engine oil

1.3 Removing and installing sump

1.4 Removing and installing lower part of sump

1.5 Removing and installing upper part of sump

1.6 Removing and installing oil pump

1.7 Removing and installing oil level and oil temperature sender G266

Engine oil cooler:

3 Oil filter, oil pressure switch

3.1 Assembly overview – oil filter housing, oil pressure switch

3.2 Removing and installing oil pressure switch F1

3.3 Removing and installing oil pressure switch for reduced oil pressure F378

3.4 Checking oil pressure

3.5 Removing and installing oil filter housing

3.6 Removing and installing oil pressure regulating valve N428

Oil circuit:

4.1 Removing and installing oil supply line

4.2 Removing and installing oil return line for turbocharger

Cooling:

1 Cooling system/coolant

1.1 Connection diagram – coolant hoses

1.2 Checking cooling system for leaks

1.3 Draining coolant

1.4 Filling with coolant

1.5 Checking filling quality of cooling system

1.6 Checking electric vacuum pump VAS 6096/2

1.7 Flushing cooling system

2 Coolant pump, regulation of cooling system

2.1 Assembly overview – coolant pump, thermostat

2.2 Assembly overview – electric coolant pump

2.3 Assembly overview – coolant temperature sender

2.4 Removing and installing electric coolant pump

2.5 Removing and installing coolant pump

2.6 Removing and installing thermostat

2.7 Checking thermostat

2.8 Removing and installing coolant valve for cylinder head N489

2.9 Removing and installing coolant temperature sender G62

2.10 Removing and installing radiator outlet coolant temperature sender G83

Coolant pipe:

3.1 Assembly overview – coolant pipes

3.2 Removing and installing coolant pipes

Radiator, radiator fan:

4.1 Assembly overview – radiator/radiator fan

4.2 Assembly overview – radiator cowl and radiator fan

4.3 Removing and installing radiator

4.4 Removing and installing water radiator for charge air cooling circuit

4.5 Removing and installing radiator cowl

4.6 Removing and installing radiator fan

Turbocharging/supercharging:

1 Turbocharger

1.1 Assembly overview – turbocharger

1.2 Removing and installing turbocharger

1.3 Renewing vacuum unit for turbocharger

1.4 Removing and installing connection for turbocharger

Charge air system:

2.1 Assembly overview – charge air system

2.2 Removing and installing charge pressure sender G31

2.3 Checking charge air system for leaks

2.4 Removing and installing air pipe

2.5 Checking charge air cooler for leaks

Mixture preparation – injection:

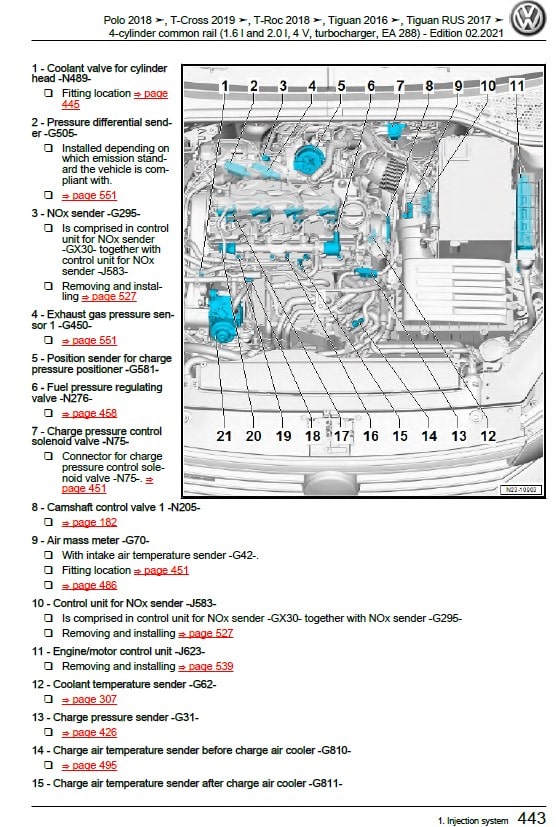

1 Injection system

1.1 Schematic overview – fuel system

1.2 Overview of fitting locations – injection system

1.3 Filling/bleeding fuel system

1.4 Checking fuel system for leaks

2 Vacuum system

2.1 Connection diagram – vacuum system

2.2 Checking vacuum system

Injectors/high-pressure accumulator (rail):

3.1 Assembly overview – injectors

3.2 Assembly overview – fuel rail

3.3 Adapting correction values for injectors

3.4 Testing injectors

3.5 Checking return flow rate of injectors with engine running

3.6 Checking return flow rate of injectors at starter speed

3.7 Testing jammed-open injectors

3.8 Removing and installing injectors

3.9 Removing and installing high-pressure lines

3.10 Removing and installing fuel rail

Air filter:

4.1 Assembly overview – air filter housing

4.2 Removing and installing air filter housing

4.3 Removing and installing air guide on lock carrier

Intake manifold:

5.1 Assembly overview – intake manifold

5.2 Removing and installing intake manifold

5.3 Removing and installing throttle valve module J338

Senders and sensors:

6.1 Removing and installing fuel pressure regulating valve N276

6.2 Checking fuel pressure regulating valve N276

6.3 Removing and installing fuel pressure sender G247

6.4 Removing and installing air mass meter G70/intake air temperature sender G42

6.5 Removing and installing pressure differential sender G505

6.6 Removing and installing exhaust gas pressure sensor 1 G450

6.7 Removing and installing NOx sender 2 G687

6.8 Removing and installing charge air temperature sender ahead of charge air cooler G810

6.9 Removing and installing charge air temperature sender after charge air cooler G811

6.10 Removing and installing fuel temperature sender G81

6.11 Removing and installing control unit for NOx sender GX30

6.12 Removing and installing temperature and pressure sender for low-pressure fuel system GX20

Engine/motor control unit:

7.1 Removing and installing engine control unit J623

7.2 Removing and installing engine control unit J623 (with protective housing)

8 High-pressure pump

8.1 Assembly overview – high-pressure pump

8.2 Removing and installing high-pressure pump

Lambda probe:

9.1 Assembly overview – Lambda probe

9.2 Removing and installing Lambda probe

Exhaust system:

1 Exhaust pipes and silencers

1.1 Assembly overview – silencers

1.2 Assembly overview – front exhaust pipe

1.3 Removing and installing front exhaust pipe

1.4 Separating exhaust pipes from silencers

1.5 Removing and installing silencer

1.6 Aligning exhaust system free of stress

1.7 Checking exhaust system for leaks

1.8 Installation position of clamp

1.9 Align end exhaust pipes

1.10 Removing and installing bracket for front exhaust pipe

Emission control:

2.1 Assembly overview – emission control

2.2 Removing and installing catalytic converter

2.3 Removing and installing particulate filter

2.4 Removing and installing emission control module

2.5 Removing and installing exhaust flap control unit J883

SCR system (selective catalytic reduction):

3.1 Assembly overview – tank for reducing agent

3.2 Assembly overview – reducing agent supply line

3.3 Assembly overview – delivery module for reducing agent

3.4 Assembly overview – filler tube for reducing agent tank

3.5 Removing and installing reducing agent tank

3.6 Removing and installing front section of reducing agent supply line

3.7 Removing and installing delivery module for reducing agent

3.8 Removing and installing injector for reduction agent N474

3.9 Removing and installing control unit for reducing-agent heater J891

3.10 Assembly overview – injector for reducing agent

3.11 Draining reducing agent tank

3.12 Removing and installing rear section of reducing agent supply line

3.13 Removing and installing filler pipe for reducing agent tank

3.14 Disconnecting reducing agent supply line

3.15 SCR – resetting learnt values

Exhaust gas temperature regulation:

4.1 Assembly overview – exhaust gas temperature regulation

4.2 Removing and installing exhaust gas temperature sender 1 G235

4.3 Removing and installing exhaust gas temperature sender 2 G448

4.4 Removing and installing exhaust gas temperature sender 3 G495

4.5 Removing and installing exhaust gas temperature sender 4 G648

Exhaust gas recirculation:

5.1 Assembly overview – exhaust gas recirculation

5.2 Assembly overview – exhaust gas recirculation valve 1 GX5

5.3 Removing and installing exhaust gas recirculation cooler

5.4 Removing and installing exhaust gas recirculation valve 1 GX5

5.5 Removing and installing exhaust gas recirculation valve 2 GX6

5.6 Removing and installing exhaust gas recirculation temperature sensor G98

5.7 Checking exhaust gas recirculation cooler for leaks

Glow plug system:

1 Glow plug system

1.1 Assembly overview – glow plug system

1.2 Removing and installing glow plug

1.3 Removing and installing automatic glow period control unit J179

1.4 Removing and installing Hall sender G40

1.5 Removing and installing engine speed sender G28

4-cylinder direct injection engine (1.5 l engine, 4V, EA 211, turbocharger) – Engine ID: DAC A, DAD A, DAC B, DPB A, DPB E, DPC

Technical data:

1 Safety information

1.1 Safety measures when working on fuel supply

1.2 Safety measures when working on vehicles with a start/stop system

1.3 Safety precautions when using testers and measuring instruments during a road test

1.4 Safety precautions when working on the cooling system

1.5 Safety precautions when working on ignition system

Identification:

2.1 Engine number/engine data

3 Repair instructions

3.1 Rules for cleanliness

3.2 General information

3.3 General repair instructions

3.4 Foreign objects in engine

3.5 Contact corrosion

3.6 Routing and attachment of lines

3.7 Fitting radiator and condensers

3.8 Checking vacuum system

Removing and installing engine:

1 Removing and installing engine

1.1 Removing engine

1.2 Separating engine and gearbox

1.3 Securing engine on engine and gearbox support

1.4 Installing engine

Assembly mountings:

2.1 Assembly overview – assembly mountings

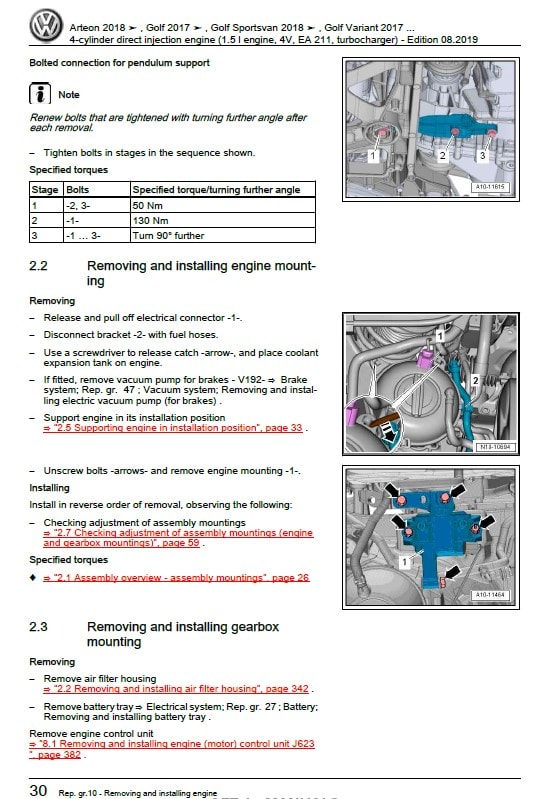

2.2 Removing and installing engine mounting

2.3 Removing and installing gearbox mounting

2.4 Removing and installing pendulum support

2.5 Supporting engine in installation position

2.6 Adjusting assembly mountings

2.7 Checking adjustment of assembly mountings (engine and gearbox mountings)

Engine cover panel:

3.1 Removing and installing engine cover

13 – Crankshaft group

1 Cylinder block (pulley end)

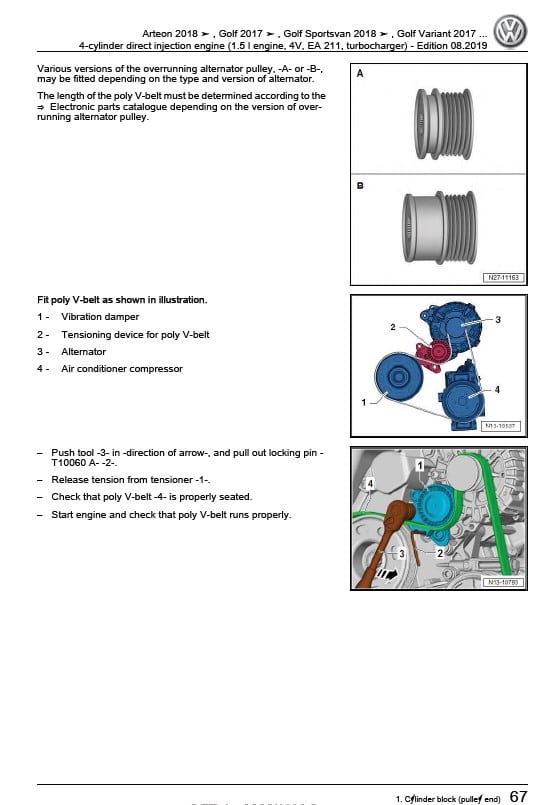

1.1 Assembly overview – poly V-belt drive

1.2 Removing and installing poly-V belt

1.3 Removing and installing tensioner for poly V-belt

1.4 Removing and installing vibration damper

1.5 Removing and installing engine support

1.6 Renewing crankshaft oil seal – belt pulley end

Cylinder block, gearbox end:

2.1 Assembly overview – cylinder block, gearbox end

2.2 Removing and installing flywheel

2.3 Removing and installing sealing flange on gearbox side

Crankshaft:

3.1 Renewing needle bearing in crankshaft

3.2 Crankshaft dimensions

3.3 Measuring axial clearance of crankshaft

Pistons and conrods:

4.1 Assembly overview – pistons and conrods

4.2 Removing and installing pistons

4.3 Checking pistons and cylinder bores

4.4 Separating new conrod

4.5 Checking radial clearance of conrods

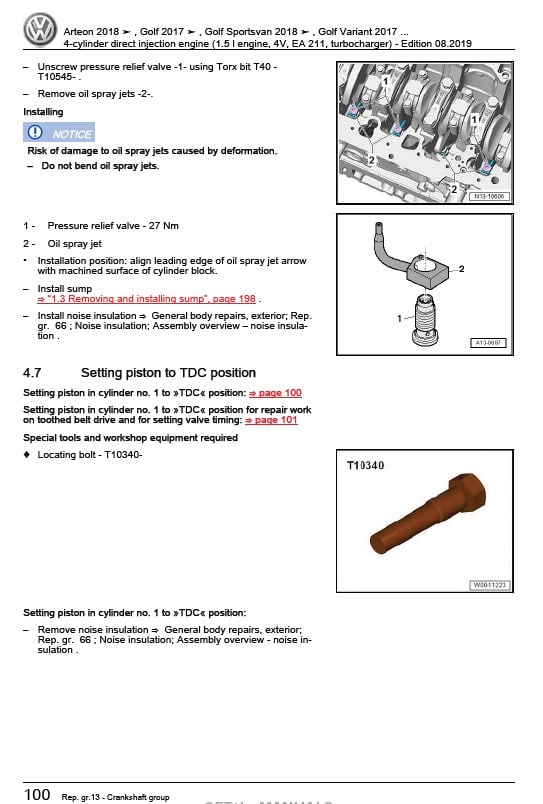

4.6 Removing and installing oil spray jets

4.7 Setting piston to TDC position

Cylinder head, valve gear:

1 Cylinder head

1.1 Assembly overview – cylinder head

1.2 Assembly overview – camshaft housing

1.3 Removing and installing cylinder head

1.4 Removing and installing camshaft housing

1.5 Checking compression

Toothed belt drive:

2.1 Assembly overview – toothed belt cover

2.2 Assembly overview – toothed belt

2.3 Assembly overview – valve timing tool

2.4 Removing and installing toothed belt guard

2.5 Removing and installing toothed belt

2.6 Preassembling and installing valve timing tool

2.7 Checking valve timing

2.8 Adjusting valve timing

2.9 Removing toothed belt from camshaft

Valve gear:

3.1 Assembly overview – valve gear

3.2 Removing and installing camshaft oil seal

3.3 Removing and installing camshaft adjuster

3.4 Removing and installing cam actuators

3.5 Removing and installing inlet camshaft control valve 1 N727

3.6 Removing and installing exhaust camshaft control valve 1 N318

3.7 Removing and installing valve stem seals

3.8 Removing and installing holder for oil seal

Inlet and exhaust valves:

4.1 Checking valve guides

4.2 Checking valves

4.3 Valve dimensions

Lubrication:

1 Sump, oil pump

1.1 Assembly overview – sump/oil pump

1.2 Engine oil:

1.3 Removing and installing sump

1.4 Removing and installing oil pump

1.5 Removing and installing oil level and oil temperature sender G266

Engine oil cooler:

2.1 Assembly overview – engine oil cooler

2.2 Removing and installing engine oil cooler

Crankcase ventilation:

3.1 Assembly overview – crankcase breather system

3.2 Removing and installing oil separator

Oil filter, oil pressure switch:

4.1 Assembly overview – oil pressure switches/oil pressure control

4.2 Removing and installing oil pressure sender G10

4.3 Checking oil pressure and oil pressure switch

4.4 Removing and installing oil filter housing

4.5 Removing and installing oil pressure regulating valve N428

Cooling:

1 Cooling system/coolant

1.1 Connection diagram – coolant hoses

1.2 Checking cooling system for leaks

1.3 Draining and adding coolant

1.4 Flushing cooling system

Coolant pump, regulation of cooling system:

2.1 Assembly overview – coolant pump, thermostat

2.2 Assembly overview – electric coolant pump

2.3 Assembly overview – coolant temperature sender

2.4 Removing and installing electric coolant pump

2.5 Removing and installing coolant pump

2.6 Removing and installing toothed belt pulley for coolant pump

2.7 Removing and installing coolant temperature sender G62

2.8 Removing and installing radiator outlet coolant temperature sender G83

2.9 Removing and installing engine outlet coolant temperature sender G82

2.10 Removing and installing engine temperature regulation module GX33

2.11 Checking coolant pump

Coolant pipes:

3.1 Assembly overview – coolant pipes

3.2 Removing and installing coolant pipes

4 Radiator, radiator fan

4.1 Assembly overview – radiator/radiator fan

4.2 Assembly overview – radiator cowl and radiator fan

4.3 Assembly overview – radiator blind

4.4 Removing and installing radiator

4.5 Removing and installing water radiator for charge air cooling circuit

4.6 Removing and installing radiator cowl

4.7 Removing and installing radiator fan

4.8 Removing and installing radiator blind

4.9 Removing and installing radiator blind control motor V544

Turbocharging/supercharging:

1 Turbocharger

1.1 Assembly overview – turbocharger

1.2 Removing and installing turbocharger

1.3 Removing and installing connection for turbocharger

1.4 Removing and installing charge pressure control module GX34

Charge air system:

2.1 Assembly overview – charge air system

2.2 Removing and installing charge air cooler

2.3 Removing and installing charge pressure sender GX26

2.4 Checking charge air system for leaks

2.5 Removing and installing air pipe

2.6 Checking charge air cooler for leaks

Mixture preparation – injection:

1 Injection system

1.1 Overview of fitting locations – injection system

2 Air filter

2.1 Assembly overview – air filter housing

2.2 Removing and installing air filter housing

2.3 Removing and installing air guide on lock carrier

Intake manifold:

3.1 Assembly overview – intake manifold

3.2 Removing and installing intake manifold

3.3 Removing and installing throttle valve module GX3

3.4 Cleaning throttle valve module GX3

Injectors:

4.1 Assembly overview – fuel rail with injectors

4.2 Removing and installing fuel rail

4.3 Removing and installing injectors

4.4 Cleaning injectors

Senders and sensors:

5.1 Removing and installing intake manifold sender GX9

5.2 Removing and installing fuel pressure sender G247

5.3 Checking fuel pressure sender G247

5.4 Removing and installing exhaust gas pressure sensor 1 G450

5.5 Removing and installing air mass measurement module GX35

High-pressure pump:

6.1 Assembly overview – high-pressure pump

6.2 Removing and installing high-pressure pump

6.3 Removing and installing high-pressure pipe

Lambda probe:

7.1 Assembly overview – Lambda probe

7.2 Removing and installing Lambda probe

Engine control unit:

8.1 Removing and installing engine (motor) control unit J623

Exhaust system:

1 Exhaust pipes and silencers

1.1 Assembly overview – silencers

1.2 Removing and installing silencer

1.3 Separating exhaust pipes from silencers

1.4 Aligning exhaust system free of stress

1.5 Checking exhaust system for leaks

1.6 Installation position of clamp

1.7 Assembly overview – front exhaust pipe

1.8 Removing and installing bracket for front exhaust pipe

Emission control:

2.1 Assembly overview – emission control

2.2 Removing and installing catalytic converter

2.3 Removing and installing particulate filter

2.4 Removing and installing exhaust flap control unit J883

Ignition system:

1 Ignition system

1.1 Assembly overview – ignition system

1.2 Removing and installing ignition coils with output stage

1.3 Removing and installing knock sensor 1 G61

1.4 Removing and installing engine speed sender G28

1.5 Removing and installing inlet camshaft position sender G1002

1.6 Removing and installing exhaust camshaft position sender G1003

Removed 6-speed manual gearbox 0AJ

Technical data:

1 Safety information

2 Identification

3 Technical data

3.1 Capacities

4 Overview – power transmission

5 Electrical components

6 Repair notes

6.1 General repair instructions

Clutch:

1 Clutch mechanism

1.1 Assembly overview – clutch release mechanism

1.2 Repairing clutch release mechanism

2 Clutch

2.1 Assembly overview – clutch

2.2 Removing and installing clutch

Controls, housing:

1 Selector mechanism

2 Removing and installing gearbox

3 Transporting gearbox

4 Gear oil

5 Securing to engine and gearbox support

6 Dismantling and assembling gearbox

6.1 Overview – gearbox

6.2 Assembly overview – gearbox

6.3 Assembly overview – gearbox housing cover

6.4 Assembly overview – clutch housing

6.5 Assembly overview – shafts, differential, selector mechanism

6.6 Assembly overview – selector forks

6.7 Repairing selector forks

6.8 Dismantling and assembling gearbox

7 Gearbox housing, clutch housing

7.1 Assembly overview – gearbox housing and clutch housing

7.2 Assembly overview – gearbox housing cover

7.3 Repairing gearbox housing

7.4 Repairing gearbox housing cover

Gears, shafts:

1 Input shaft

1.1 Assembly overview – input shaft

1.2 Dismantling and assembling input shaft

1.3 Renewing input shaft seal

2 Output shaft

2.1 Assembly overview – output shaft

2.2 Dismantling and assembling output shaft

Final drive – differential:

1 Seals

1.1 Overview of fitting locations – seals

2 Differential

2.1 Assembly overview – differential

2.2 Dismantling and assembling differential

2.3 Adjusting differential

Avaliações

Não há avaliações ainda.