CONTENT

GENERAL

– DIMENSIONS

– SPECIFICATIONS

– VEHICLE IDENTIFICATION

– MAINTENANCE INTERVAL

– RECOMMENDED FLUIDS AND LUBRICANTS

– JACK-UP POINTS (DOTTED CIRCLES)

– PIN ARRANGEMENT OF DIAGNOSTIC CONNECTOR

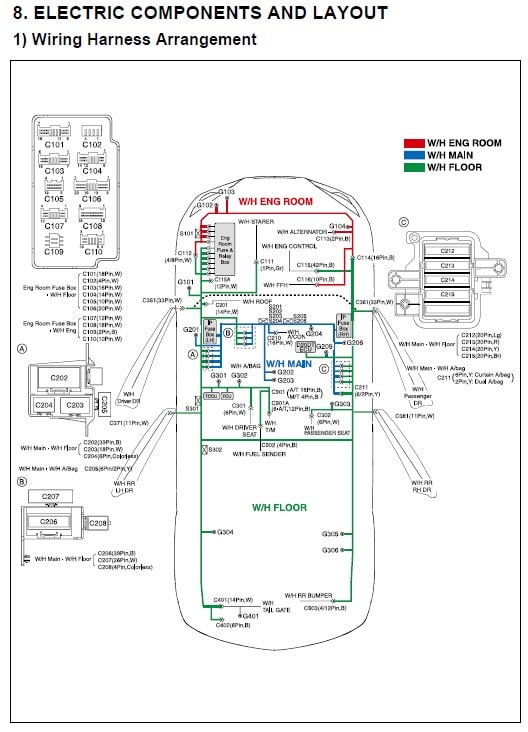

– ELECTRIC COMPONENTS AND LAYOUT

– STANDARD BOLTS SPECIFICATIONS

ENGINE GENERAL

– ENGINE ASSEMBLY LAYOUT

– ENGINE CONTROLS LAYOUT

– ELECTRICAL COMPONENTS AND PREHEATING SYSTEM

– INTAKE SYSTEM LAYOUT

– EXHAUST SYSTEM LAYOUT

– LUBRICATION SYSTEM LAYOUT

– COOLING SYSTEM LAYOUT

– FUEL SYSTEM LAYOUT

– FUEL SUPPLY SYSTEM

– CLEANNESS

– MAINTENANCE AND REPAIR

– GUIDELINES FOR SERVICE WORK SAFETY

– DURING SERVICE WORK FOR INSPECTION

– DURING SERVICE WORK FOR ELECTRIC DEVICES

– OWNER INSPECTIONS AND SERVICES

– STANDARD BOLTS SPECIFICATIONS

CRUISE CONTROL SYSTEM

– CRUISE CONTROL SWITCH

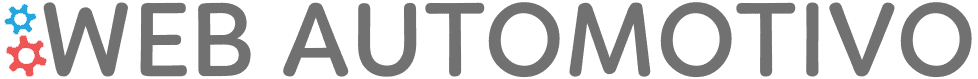

– CIRCUIT DIAGRAM

– HOW TO OPERATE CRUISE CONTROL SWITCH

ENGINE ASSEMBLY

– GENERAL

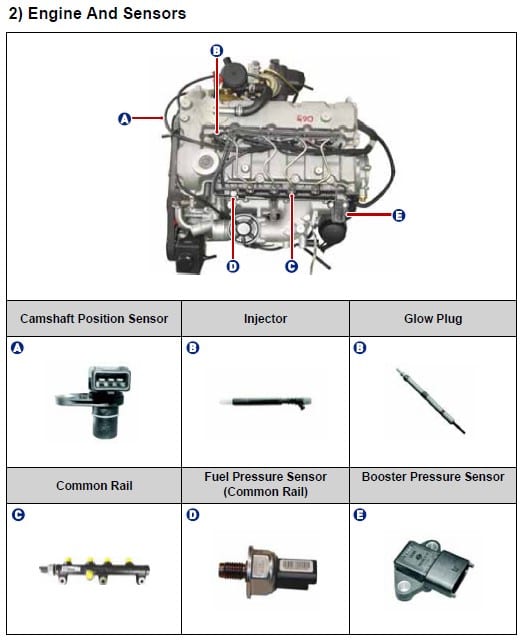

– MAJOR COMPONENTS IN ENGINE AND ENGINE COMPARTMENT

– SPECIFICATIONS AND PERFORMANCE CURVE

– TIGHTENING TORQUE

– CONFIGURATION AND FUNCTIONS

– CYLINDER HEAD

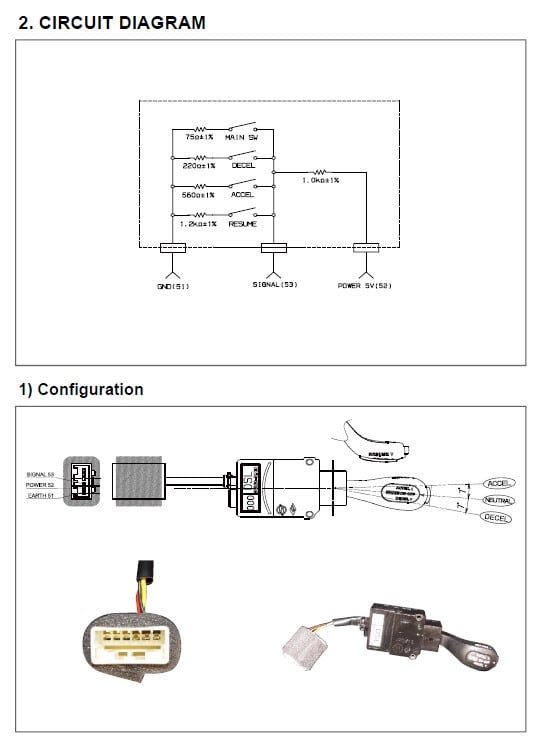

– CAMSHAFT ASSEMBLY

– TIMING CHAIN ASSEMBLY

– CYLINDER BLOCK

– CRANKSHAFT ASSEMBLY

– FLYWHEEL

– PISTON AND CONNECTING ROD

– HIGH PRESSURE PUMP(HPP)

– REMOVAL AND INSTALLATION

– GENERAL DIAGNOSIS

– DIAGNOSTIC INFORMATION AND PROCEDURE

– REMOVAL STEPS OF ENGINE ASSEMBLY

– ENGINE ACCESSORIES

– DISASSEMBLY AND REASSEMBLY OF ENGINE ASSEMBLY

– ENGINE OVERHAUL

– CYLINDER HEAD

– INTAKE/EXHAUST

– CAMSHAFT ASSEMBLY

– TIMING CHAIN

– CRANKSHAFT

– PISTON AND CONNECTING ROD

– DISASSEMBLY AND REASSEMBLY OF HIGH PRESSURE PUMP(HPP)

ENGINE FUEL SYSTEM

– GENERAL

– CAUTIONS FOR DI ENGINE

– OVERVIEW AND OPERATION PROCESS

– ELECTRONIC CONTROL OF FUEL SYSTEM

– COMPOSITION OF FUEL SYSTEM

– HYDRAULIC CYCLE IN FUEL LINE (TRANSFER AND HIGH PRESSURE LINE)

– COMPONENTS OF LOW PRESSURE TRANSFER LINE

– COMPONENTS OF HIGH PRESSURE TRANSFER LINE

– CIRCUIT DIAGRAM

– CONFIGURATION AND FUNCTIONS

– TRANSFER PUMP

– INLET METERING VALVE(IMV)

– HIGH PRESSURE PUMP

– FUEL FILTER

– PRIMING PUMP

– HIGH PRESSURE ACCUMULATOR(COMMON RAIL)

– FUEL PRESSURE SENSOR

– FUEL TEMPERATURE SENSOR

– INJECTOR

ENGINE INTAKE SYSTEM

– GENERAL

– ENGINE INTAKE SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

– INTAKE SYSTEM LAYOUT

– AIR FLOWS

– CONFIGURATION AND FUNCTIONS

– AIR FLOW SENSOR (HOT FILM AIR MASS SENSOR)

– INTERCOOLER

– INTAKE MANIFOLD ASSEMBLY

– REMOVAL AND INSTALLATION

– PRECAUTIONS WHEN INSTALLING INTAKE SYSTEM

– AIR CLEANER ELEMENTREPLACEMENT

– AIR CLEANER HOUSING

– AIR FLOW SENSOR(HOT FILM AIR MASS SENSOR)

– INTERCOOLER

– INTAKE MANIFOLD

ENGINE EXHAUST SYSTEM

– GENERAL

– INSPECTION BEFORE DIAGNOSIS

– OVERVIEW AND OPERATION PROCESS

– EXHAUST SYSTEM LAYOUT

– CONFIGURATION AND FUNCTIONS

– TUBO CHARGER ASSEMBLY

– 1913-01 VGT(VARIABLE GEOMETRY TUBOCHARGER)

– EGR VALVE AND VACUUM MODULATOR

– EXHAUST DEVICE AND MUFFLER

– REMOVAL AND INSTALLATION

– DIAGNOSIS AND MAINTENANCE For TURBO CHARGER SYSTEM

– PATH OF TUBO CHARGER DEFECT

– HOW TO DIAGNOSE

– PATH OF EXHAUST DEVICE DEFECT

– TUBO CHARGER ASSEMBLY

– TUBO CHARGER CHECK FOR VGT

– EGR VALVE

– VACUUM MODULATOR ASSEMBLY

– EXHAUST MANIFOLD

– EXHAUST PIPE

LUBRICATION SYSTEM

– GENERAL

– SPECIFICATIONS

– OIL PRESSURE SWITCH

– OVERVIEW AND OPERATION PROCESS

– LAYOUT AND OVERVIEW

– LUBRICATION DIAGRAM

– CONFIGURATION AND FUNCTIONS

– OIL PUMP

– BLOW-BY GAS REDUCTION DEVICE

– CYLINDER HEAD COVER

– OIL SEPARATOR

– OIL SPRAY NOZZLE

– OIL PAN ASSEMBLY

– REMOVAL AND INSTALLATION

– TROUBLE DIAGNOSIS

– ENGINE OIL CHANGE

– ENINE OIL FILTER CHANGE

– OIL FILTER AND COOLER

– OIL DIPSTICK GUIDE TUBE

– DISASSEMBLY OF OIL SPRAY NOZZLE

– OIL PAN AND OIL PUMP

ENGINE COOLING SYSTEM

– GENERAL

– ENGINE COOLING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

– COMPONENTS OF ENGINE COOLING

– COOLING SYSTEM FLOW

– FUNCTION DESCRIPTION OF COOLING SYSTEM

– CONFIGURATION AND FUNCTIONS

– RADIATOR

– WATER PUMP

– COOLANT RESERVOIR

– THERMOSTAT

– COOLANT TEMPERTURE SENSOR

– PREHEATING SYSTEM

– REMOVAL AND INSTALLATION

– TROUBLE DIAGNOSIS

– COOLANT LEVEL CHECK

– INSPECTION AND REPAIR

– DRAINING AND ADDING OF COOLANT

– COOLANT HOSE(INLET/OUTLET)

– SHROUD AND COOLING FAN/CLUTCH

– WATER PUMP ASSEMBLY

– THERMOSTAT

– WATER PUMP HOUSING

– RADIATOR

– REPLACEMENT OF FAN BELT

– COOLANT RESERVOIR

– PREHEATING

– PREGLOW PLUG

ECU

– CONFIGURATION AND FUNCTIONS

– ENGINE ECU – CDPF (EURO IV)

– CONNECTOR PIN OF ENGINE ECU – CDPF (EURO IV)

– ECU (ENGINE CONTROL UNIT – D20DT EU IV)

– REMOVAL AND INSTALLATION

– ENGINE ECU – CDPF (EURO IV)

CDPF

– GENERAL INFORMATION

– OVERVIEW FOR CDPF (EURO IV)

– CDPF (EURO IV) SYSTEM

– OVERVIEW AND OPERATION PROCESS

-. OVERVIEW

– CDPF (EURO IV) SYSTEM CONTROL

– SOOT FILTERING AND BURNING PROCEDURES

– COMPONENTS OF CDPF SYSTEM

– COMFIGURATION AND FUNCTIONS

– FRONT EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

– REAR EXHAUST GAS TEMPERATURE SENSOR

– DIFFERENTIAL PRESSURE SENSOR – CDPF (EURO IV)

– REMOVAL AND INSTALLATION

– FRONT EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

– REAR EXHAUST GAS TEMPERATURE SENSOR – CDPF (EURO IV)

– DIFFERENTIAL PRESSURE SENSOR – CDPF (EURO IV)

– CDPF ASSEMBLY – CDPF (EURO IV)

CRUISE CONTROL SYSTEM

– OVERVIEW AND OPERATION PROCESS

– CRUISE CONTROL SWITCH

– CIRCUIT DIAGRAM

– HOW TO OPERATE CRUISE CONTROL SWITCH

– REMOVAL AND INSTALLATION

– CRUISE CONTROL SWITCH

ENGINE ASSEMBLY

– GENERAL

– DESCRIPTION AND OPERATION

– G23D ENGINE ASSEMBLY

– G23D ENGINE STRUCTURE

– DIAGNOSTIC INFORMATION AND PROCEDURE

– GENERAL DIAGNOSIS

– SPECIFICATIONS

– CONFIGURATION AND FUNCTIONS

– CRANKCASE VENTILATION SYSTEM

– OIL CIRCULATION

– REMOVAL AND INSTALLATION

– ENGINE ASSEMBLY

– ALTERNATOR

– EINGINE MOUNT

– POLY V-BELT

– POLY V-BELT INSPECTION

– TENSIONING DEVICE

– TENSIONING DEVICE SHOCK ABSORBER

– CYLINDER HEAD COVER

– CYLINDER HEAD FRONT COVER

– CYLINDER HEAD

– TIMING GEAR CASE COVER

– CRANKSHAFT SEALING REAR COVER

– BELT PULLEY AND VIBRATION DAMPER

– CRANKSHAFT FRONT RADIAL SEAL

– CRANKSHAFT REAR RADIAL SEAL

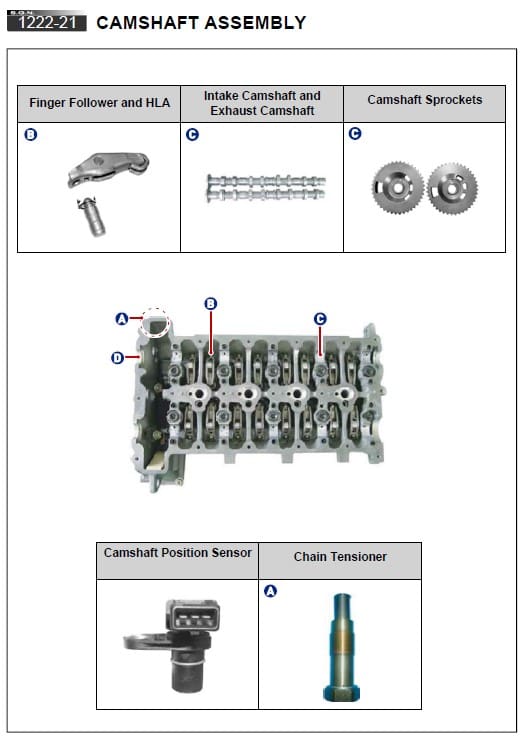

– CRANKSHAFT

– ARRANGEMENT OF THE THRUST BEARING AND THE MAIN BEARING

– FLYWHEEL/ DRIVE PLATE

– CAMSHAFT ADJUSTER

– CAMSHAFT

– INSPECTION AND ADJUSTMENT OF CAMSHAFT TIMING POSITION

– REMOVAL AND INSTALLATION

– VALVE SPRING

– VALVE STEM SEAL

– CHAIN TENSIONER

– TIMING CHAIN

– TENSIONING RAIL

– CYLINDER HEAD GUIDE RAIL

– CRANKCASE GUIDE RAIL

– CRANKSHAFT SPROCKET

– PISTON

– CONNECTING ROD

– PISTON RING

– OIL PAN

– ENGINE OIL AND OIL FILTER ELEMENT

– OIL PUMP

– OIL PRESSURE RELIEF VALVE

– OIL NON-RETURN VALVE

– OIL DIPSTICK GUIDE TUBE

– REPAIR OF CORE PLUGS IN CRANKCASE

– CYLINDER BORE

– CRANKCASE MATING SURFACE

– CYLINDER HEAD MATING SURFACE

ENGINE INTAKE SYSTEM

– GENERAL

– SPECIFICATIONS

– CONFIGURATION AND FUNCTIONS

– RESONANCE FLAP

– AIR CLEANER AND INTAKE AIR DUCT

– REMOVAL AND INSTALLATION

– AIR CLEANER AND INTAKE AIR DUCT

– INTAKE MANIFOLD

ENGINE EXHAUST SYSTEM

– GENERAL

– SPECIFICATION

– OVERVIEW AND OPERATION PROCESS

– DESCRIPTION AND OPERATION

– REMOVAL AND INSTALLATION

– EXHAUST LINE

ENGINE COOLING SYSTEM

– GENERAL

– GENERAL SPECIFICATIONS

– FASTENER TIGHTENING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

– COMPONENT LOCATOR

– DESCRIPTION AND OPERATION

– PWM (PULSE WIDTH MODULATION) ELECTRIC FAN OPERATION

– REMOVAL AND INSTALLATION

– DTC FOR PWM ELECTRIC FAN

– DIAGNOSTIC INFORMATION AND PROCEDURE

– REPAIR INSTRUCTIONS ONVEHICLE SERVICE

– WATER PUMP

– THERMOSTAT AND THERMOSTAT HOUSING ASSEMBLY

– PWM CONTROLLER UNIT

– PWM ELECTRIC FAN AND SHROUD ASSEMBLY

ENGINE ELECTRIC DEVICES

– GENERAL

– DIAGNOSTIC INFORMATION AND PROCEDURE

– OVERVIEW AND OPERATION PROCESS

– DESCRIPTION AND OPERATION

– REMOVAL AND INSTALLATION

– GENERATOR REPAIR INSTRUCTIONS

– STARTER REPAIR INSTRUCTIONS

– BATTERY REPAIR INSTRUCTIONS

– SPARK PLUG AND IGNITION COIL REPAIR INSTRUCTIONS

ELECTRIC GENERAL

– GENERAL

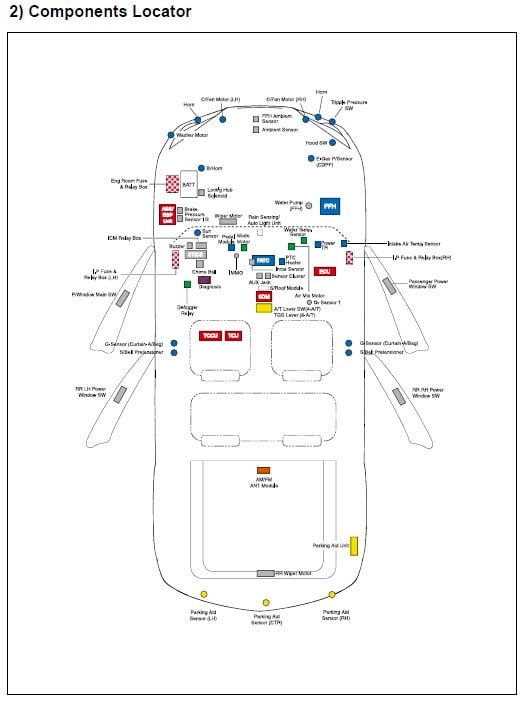

– LOCATIONS OF INTERIOR UNITS AND SENSORS

– LOCATION AND COMPARTMENT OF INTERIOR SWITCHES

– SWITCHES, UNITS AND SENSORS IN ENGINE COMPARTMENT

– ELECTRIC COMPONENTS AND LAYOUT

– DIAGNOSTIC CONNECTOR

– PAS

GENERAL

– COMPONENT SPECIFICATIONS

– CAUTIONS ON PARKING AID SYSTEM OVERVIEW AND OPERATION PROCESS

– SYSTEM OVERVIEW

– ALARM INTERVAL

– TROUBLESHOOTING OF SENSOR

– CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

– PARKING AID SENSOR

AUDIO SYSTEM

– OVERVIEW AND INSTALLATION

– AUDIO SYSTEM OVERVIEW

– CIRCUIT DIAGRAM OF AUDIO SYSTEM

– CONFIGURATION AND FUNCTION

– COMBINATION ANTENNA

– USB/AUX MODULE

– REMOVAL AND INSTALLATION

– AV HEAD UNIT

– FRONT DOOR SPEAKER AND REAR DOOR SPEAKER

– DOOR TWEETER SPEAKER

– COMBINATION ANTENNA

– USB/AUX MODULE

FUSE AND RELAY

– GENERAL INFORMATION

– GENERAL INFORMATION

– OVERVIEW AND OPERATING PROCESS

– OVERVIEW

– FUSE & RELAY MOUNTING LOCATION

– CAPACITY AND NAME OF FUSE AND RELAY IN ENGINE COMPARTMENT

– CAPACITY AND NAME OF INTERIOR FUSE AND RELAY

– OPERATING PROCESS OF ICM BOX

– CONFIGURATION AND FUNCTIONS

– CONFIGURATION OF PCB IN ICM BOX AND FUNCTION OF CONNECTOR

– CIRCUIT DIAGRAM FOR FUSE & RELAY BOX IN ENGINE COMPARTMENT

– CIRCUIT DIAGRAM FOR INTERIOR FUSE & RELAY BOX ON DRIVER SIDE

– CIRCUIT DIAGRAM FOR INTERIOR FUSE & RELAY BOX ON PASSENGER SIDE

– REMOVAL AND INSTALLATION

– ICM BOX

STICS

– GENERAL

– OVERVIEW

– MAJOR CHANGES

– SPECIFICATIONS

– OVERVIEW AND OPEARATION PROCESS

– OVERVIEW

– FUNCTIONS AND SPECIFICATIONS

– CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

– REKES KEY CODING

– DIAGNOSIS TROUBLE CODE AND HEIP TIPS

– STICS

IMMOBILIZER SYSTEM

– OVERVIEW AND OPERATION PROCESS

– OVERVIEW

– BASIC FUNCTIONS OF IMMOBILIZER KEY

– OTHER FUNCTIONS IN SYSTEM

– REKES OPERATION LOGIC

– CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

– IMMOBILIZER CODING PROCEDURE

– IMMOBILIZER UNIT

CLUSTER

– GENERAL

– DESCRIPTIONS OF INDICATOR DISPLAY

– WARNING & INDICATOR PANEL

– CLUSTER OPERATION PROCESS

– CIRCUIT DIAGRAM

– CONFIGURATION AND FUNCTIONS

– COFIGURATION OF CLUSTER

– REMOVAL AND INSTALLATION

– METER CLUSTER

LAMP

– OVERVEIW AND OPERATION PROCESS

– LOCATIONS OF EXTERIOR LAMPS

– INTERIOR LAMPS

– LAMP OPERATION LOGIC

– CONFIGURATION AND FUNCTIONS

– FRONT LAMPS

– REAR LAMP

– INTERIOR LAMPS

– REMOVAL AND INSTALLATION

– HEAD LAMPS

– FOG LIGHT

– SIDE REPEATER

– REAR COMBINATION LAMP

– LICENSE PLATE LAMP

– HIGH MOOUNTED STOP LAMP

– REAR FOG LIGHT

– INTERIOR LAMPS

SWITCH

– GENERAL

– SWITCH ARRANGEMENT

– CONFIGURATION AND FUNCTIONS

– CENTER FASCIA & BEZEL SWITCH ASSEMBLY

– OUTSIDE REARVIEW MIRROR SWITCH BEZEL ASSEMBLY

– INTERIOR LAMP SWITCH

– MAIN POWER WINDOW SWITCH

– AUDIO REMOTE CONTROL SWITCH ON STEERING WHEEL

– MULTIFUNCTION SWITCH

– TAIL GATE OPEN SWITCH

– DIGITAL CLOCK

– HORN (INCLUDING THEFT WARNING HORN)

– REMOVAL AND INSTALLATION

– HAZARD & SWITCH ASSEMBLY

– OUTSIDE REARVIEW MIRROR SWITCH BEZEL ASSEMBLY

– OUTSIDE REARVIEW MIRROR FOLDING UNIT

– OVERHEAD CONSOLE SWITCH

– MAIN POWER WINDOW SWITCH

– AUDIO REMOTE CONTROL SWITCH

– MULTIFUNCTION SWITCH

– TAIL GATE OPEN SWITCH

– CIGARETTE LIGHTER

– FRONT POWER OUTLET

– REAR POWER OUTLET

– DIGITAL CLOCK

– HORN

WIPER & WASHER

– OVERVIEW AND OPERATION PROCESS

– SYSTEM LAYOUT AND FUNCTION

– SYSTEM LAYOUT OF WIPER AND WASHER (WITH RAIN SENSOR)

-. WIPER & WASHER RELATED FUNCTION AND SPECIFICATION

– WIPER AND WASHER SYSTEM RELATED CIRCUIT DIAGRAM

– REMOVAL AND INSTALLATION

– CORRECTION OF FRONT WIPER

– FRONT WIPER ASSEMBLY

– REAR WIPER ASSEMBLY

– WASHER FLUID RESERVOIR TANK

– WASHER NOZZLE

RAIN SENSOR

– OVERVIEW AND OPERATION PROCESS

– SYSTEM LAYOUT AND OVERVIEW

– RAIN SENSING OPERATION

– RAIN SENSOR RELATED CIRCUIT

– FUNCTIONS AND SPECIFICATIONS OF RAIN SENSING WIPER

– OPERATION MODE OF RAIN SENSING WIPER SYSTEM

– REMOVAL AND INSTALLATION

– FUNCTIONS AND CHECKS OF RAIN SENSOR

– DIAGNOSIS PROCEDURES

– RAIN SENSOR

ION 4-SPEED

– GENERAL

– SPECIFICATIONS

– FASTENER TIGHTENING SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

– DESCRIPTION AND OPERATION OF AUTOMATIC TRANSMISSION

– APPEARANCE

– SHIFT PATTERN DIAGRAM

– OPERATORS INTERFACES

– CONTROL SYSTEMS

– ELECTRONIC CONTROL SYSTEM

– HYDRAULIC CONTROL SYSTEM

– POWER FLOWS

– CONFIGURATION AND FUNCTIONS

TCU

– ACCELERATOR PEDAL SENSOR

– REMOVAL AND INSTALLATION

– DIAGNOSTIC INFORMATION AND PROCEDURES

– REBUILD WARNINGS

– FRONT AND REAR BAND ADJUSTMENT

– SYMPTOM DIAGNOSIS

– TROUBLE CODE DIAGNOSIS

– ION AUTOMATIC TRANSMISSION ASSEMBLY

– VALVE BODY

– DISASSEMBLY OF TRANSMISSION

– ASSEMBLY OF TRANSMISSION

– 3642-18 GEAR SHIFT CONTROL LEVER

– TCU

STEERING

– GENERAL

– OVERVIEW

– SPECIFICATIONS

– OVERVIEW AND OPERATION

– SYSTEM LAYOUT

– COMPONENTS

– REMOVAL AND INSTALLATION

– TROUBLE DIAGNOSIS

– INSPECTIONS OF POWER STEERING SYSTEM

– STEERING COLUMN SHAFT

– LOWER SHAFT

– STEERING GEAR BOX

– STEERING GEAR PUMP

DSI M78 6-SPEED A/T

– GENERAL INFORMATION

– DSI M78 6-SPEED AUTOMATIC TRANSMISSION GENERAL

– STRUCTURE CHARACTERISTICS AND SPECIFICATIONS

– TIGHTENING TORQUE

– OVERVIEW AND OPERATION PROCESS

– GENERAL DESCRIPTION

– ADVANCED SIX SPEED FEATURES

– FUNCTION OF EACH MODE

– LIMP HOME MODE

– TRANSMISSION ELECTRONIC CONTROL SYSTEM

– CONFIGURATION OF CAN RELATED TO TCU

– POWER TRAIN

– CONFIGURATION AND FUNCTIONS

– TGS LEVER

– DSI M78 6-SPEED A/T ASSEMBLY

– VALVE BODY

– TCU

– INHIBITOR SWITCH

– REMOVAL AND INSTALLATION

– FLUID LEVEL INSPECTION

TRANSMISSION RESET PROCEDURE (REPLACEMENT TRANSMISSION)

– DIAGNOSIS AND TESTING

– WIRING DIAGRAM

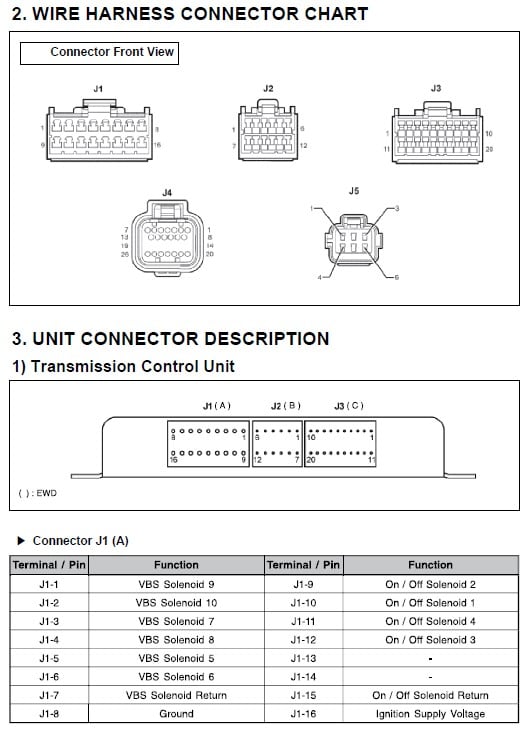

– WIRE HARNESS CONNECTOR CHART

– UNIT CONNECTOR DESCRIPTION

– TROUBLE CODE EIAGNOSIS

– DIAGNOSTIC TROUBLE CODE LIST

– SYSTEM DIAGNOSIS

– MAINTENANCE OPERATIONS

– OIL TEST

– STALL TEST

– TRANSMISSION RESET PROCEDURE (REPLACEMENT TRANSMISSION)

– FLUID LEVEL INSPECTION

– TRANSMISSION COOLER AND HYDRAULIC LINE FLUSHING PROCEDURE

– LUBRICATION

– TRANSMISSION COOLER AND HYDRAULIC LINE FLUSHING PROCEDURE (NEW TRANSMISSION)

TGS LEVER

– OVERVIEW AND OPERATION PROCESS

– INTRODUCTION

– FUNCTIONS OF THE SELECTOR LEVER

– MODE SWITCH

– PARKING LOCK SYSTEM

– CONFIGURATION AND FUNCTIONS

– SELECTOR LEVER CONTROL UNIT

– REMOVAL AND INSTALLATION

– SHIFT ROD POSTION ADJUSTMENT

– TGS LEVER

MANUAL TRANSMISSION

– GENERAL

– OVERVIEW AND CHARACTERISTICS OF MANUAL TRANSMISSION

– SPECIFICATIONS AND TIGHTENING TORQUE OF MANUAL TRANSMISSION

– OVERVIEW AND OPERATION PROCESS

– MANUAL TRANSMISSION SYSTEM

– CONFIGURATION AND FUNCTIONS

– MANUAL TRANSMISSION LOCATION

– MANUAL TRANSMISSION SYSTEM COMPONENTS

– SHIFTING MECHANISM

– REMOVAL AND INSTALLATION

– DIAGNOSTIC INFORMATION AND PROCEDURES

– OIL CHECK/CHANGE OF MANUAL TRANSMISSION

– MANUAL TRANSMISSION

– MANUAL TRANSMISSION OVERHAUL

– TRANSMISSION ADAPTER

– SHIM ADJUSTMENT

CLUTCH

– GENERAL

– CLUTCH SPECIFICATIONS

-. TIGHTENING TORQUE

– OVERVIEW AND OPERATION PROCESS

-. FUNCTION AND OVERVIEW

– CONFIGURATION AND FUNCTIONS

– CLUTCH MASTER CYLINDER

– CLUTCH RELEASE CHAMBER

– CLUTCH ASSEMBLY

– CLUTCH PEDAL

– REMOVAL AND INSTALLATION

– CLUTCH TROUBLE DIAGNOSIS

– CLUTCH INSPECTION AND MAINTENANCE

– CLUTCH AIR BLEEDING

– CLUTCH ASSEMBLY

– CLUTCH REPLACEMENT

– CONCENTRIC SLAVE CTLINDER

– CLUTCH MASTER CYLINDER

– CLUTCH PEDAL

– CLUTCH CHAMBER

AXLE

– GENERAL

-. SPECIFICATIONS OF AXLE

– OVERVIEW AND OPERATION PROCESS

– OVERVIEW OF AXLE

– CONFIGURATION AND FUNCTIONS

– FRONT AXLE

– LINK TYPE REAR AXLE

– REMOVAL AND INSTALLATION

– TROUBLE DIAGNOSIS

– INSPECTION OF RING GEAR TOOTH CONTACT PATTERN

– FRONT AXLE ASSEMBLY

– AXLE SHAFT

– AXLE HOUSING

– REAR AXLE SHAFT(DISC BRAKE TYPE)

– REAR AXLE HOUSING

TRANSFER CASE

– GENERAL

– OVERVIEW

– SPECIFICATIONS

– OVERVIEW AND OPERATION PROCESS

– STRUCTURE

-. SYSTEM LAYOUT AND OPERATION

– LOCKING HUB SYSTEM

– POWER FLOW

– CONFIGURATION AND FUNCTION

– TRANSFER CASE

– COMPONENTS OF IWE (INTEGRATED WHEEL END)

– TCCU(TRANSFER CASE CONTROL UNIT)

– REMOVAL AND INSTALLATION

– PART TIME TRANSFER CASE GENERAL DIAGNOSIS

– VACUUM LOCKING HUB CHECK

– OIL LEVEL CHECK AND CHANGE

– SELF-DIAGNOSIS TEST

– TCCU DIAGNOSTIC TROUBLE CODE

– PART TIME TRANSFER CASE

– TRANSFER CASE MOTOR

– IWE (INTEGRATED WHEEL END)

– LOCKING HUB ACTUATOR ASSEMBLY

– TCCU

SUSPENSION

– GENERAL

– SPECIFICATIONS OF SUSPENSION

– WHEEL ALIGNMENT

– CONFIGURATION AND FUNCTION

– FRONT SUSPENSION

– REAR SUSPENSION (5-LINK TYPE)

– REMOVAL AND INSTALLATION

– TROUBLE DIAGNOSIS OF REAR SUSPENSION

– FRONT SUSPENSION-UPPER ARM

– FRONT SUSPENSION- COIL SPRING & SHOCK ABSORBER ASSEMBLY

– FRONT SUSPENSIONSTABILIZER BAR

– FRONT SUSPENSIONLOWER ARM

– REAR SUSPENSION (5 LINK TYPE)

ESP

– GENERAL

– SYSTEM GENERAL

-. SECTIONAL DRAWING

-. SPECIFICATIONS

– BRAKE OPERATION AND NOISE

– ESP SYSTEM RELATED PRECAUTIONS

– OVERVIEW AND OPERATION PROCESS

– OVERVIEW OF ESP(ELECTRONIC STABILITY PROGRAM) SYSTEM

– COMPONENTS OF ESP

– PRINCIPLE OF ESP

– PRINCIPLE OF BAS(BRAKE ASSIST SYSTEM)

– PRINCIPLE ARP(ACTIVE ROLL-OVER PROTECTION)

– PRINCIPLE OF HDC(HILL DESCENT CONTROL)

– INPUT AND OUTPUT DIAGRAM OF ESP SYSTEM

– HYDRAULIC CIRCUIT DIAGRAM OF ESP SYSTEM

– HYDRAULIC PRESSURE FOR EACH ESP OPERATING RANGE

– HYDRAULIC CIRCUIT OF BAS (BRAKE ASSIST SYSTEM)

– COMPONENTS OF ABS SYSTEM

– CONFIGURATION AND FUNCTIONS

– HECU OF ESP

– HECU OF ABS

– PRESSURE SENSOR

– SENSOR CLUS

– SWAS(STEERING WHEEL ANGLE SENSOR)

– ESP OFF SWITCH

– ASS(Active Wheel Speed Sensor)

– REMOVAL AND INSTALLATION

– ESP SYSTEM AIR BLEEDING

– SENSOR CALIBRATION AND FORCED OPERATION OF ACTUATOR SENSOR VALUE

– ABS/ESP TROUBLE DIAGNOSIS

– CAUTIONS WHEN REMOVING FRONT WHEEL SPEED SENSOR-ESP

– CAUTIONS WHEN REMOVING FRONT WHEEL SPEED ABS

– HECU-ESP

– HECU-ABS

– FRONT WHEEL SPEED SENSOR

– REAR WHEEL SPEED SENSOR

– PRESSURE SENSOR

– SENSOR CLUSTER

AIR BAG

– GENERAL

– OVERVIEW (INCLUDING CURTAIN AIR BAGS)

– OVERVIEW AND OPERATION PROCESS

– LOCATION AND RELATED COMPONENTS

– AIR BAG SYSTEM OPERATION PROCESS

– AIR BAG MODULE AND RELATED COMPONENTS

– REMOVAL AND INSTALLATION

– TROUBLE

– DRIVER AIR BAG

– PASSENGER AIR BAG

– CURTAIN AIR BAG

– CONTACT COIL

– AIR BAG(SDM)

– CURTAIN AIR BAG G SENSOR

SEAT

– OVERVIEW AND OPERATION PROCESS

– COMPOSITION OF SEAT

– FUNCTIONS OF SEAT

– COMPONENTS OF SEAT BELT

– REMOVAL AND INSTALLATION

– SEAT MOUNTING POINTS

– SEAT ASSEMBLY

– SEAT BELT

SUNROOF

– OVERVIEW AND OPERATION PROCESS

– COMPONENTS AND LOCATIONS

– OPERATION AND FUNCTION

– CONFIGURATION AND FUNCTION

– COMPONENTS OF SUNROOF

– REMOVAL AND INSTALLATION

– RESETTING OF SUNROOF CONTROL UNIT

– TROUBLE DIAGNOSIS

– GLASS PANEL ASSEMBLY

– BELLOWS COVER

– DRAIN CHANNEL

– SUN SHADE PANEL

– SUNROOF CONTROL UNIT(SCU) AND MOTO

– SUNROOF DRAIN HOSE

– SUNROOF ASSEMBLY

BODY INTERIOR

– OVERVIEW AND OPERATION PROCESS

– LOCATIONS

– REMOVAL AND INSTALLATION

– INSTRUMENT PANEL ASSEMBLY

– INSTRUMENT PANEL FRAME ASSEMBLY

– CENTERCONSOLE (AUTOMATIC TRANSMISSION)

– CENTER CONSOLE (MANUAL TRANSMISSION)

– SUNVISOR

– PILLAR

– HEADLINING ASSEMBLY

– OUTSIDE REARVIEW

– MIRROR

– INSIDE REARVIEW MIRROR

BODY EXTERIOR

– OVERVIEW AND OPERATION PROCESS

– COMPOSITION OF BODY EXTERIOR

– CONFIGURATION AND FUNCTION

– COMPONENT OF FRONT BUMPER ASSEMBLY

– COMPONENTS OF REAR BUMPER ASSEMBLY

– COMPONENTS OF HOOD ASSEMBLY

– COMPONENTS OF SIDE SILMOLDING

– COMPONENTS OF FRONT DOOR ASSEMBLY

– COMPONENTS OF FRONT WINDOW REGULATOR

– COMPONENTS OF REAR DOOR ASSEMBLY

– COMPONENTS OF REAR WINDOW REGULATOR

– COMPONENTS OF TAILGATE ASSEMBLY

– REMOVAL AND INSTALLATION

– HOOD ASSEMBLY

– SIDE SILMOLDING

– FENDER PANEL ASSEMBLY

– FRONT DOOR TRIM (DRIVER SIDE)

– FRONT DOOR (DRIVER SIDE)

– WINDOW REGULATOR (PASSENGER SIDE)

– REAR DOOR TRIM

– REAR DOOR ASSEMBLY

– REAR DOOR MOLDING AND PANEL

– REAR WINDOW REGULATOR

– TAILGATE TRIM

– TAILGATE ASSEMBLY

– TAILGATE LATCH AND ACTUATOR

– REAR QUARTER GLASS

BODY REPAIR

– GENERAL

– DIMENSIONS

– JACK-UP POINTS

– DESIGN CHANGES FOR IMPROVING NVH PERFORMANCE

– CONFIGURATION AND FUNCTIONS

– FRAME DIMENSIONS

– FRAME BODY MOUNTING

– WHITE BODY

– BODY DIMENSIONS

– BODY GAPS

– DOOR COMPONENTS(INCLUDING ENGINE HOOD)

– COMPONENTS OF BODY PANELS

AIR CONDITIONER

– OVERVIEW AND OPERATION PROCESS

– SYSTEM LAYOUT AND COMPONENTS

– VENTILATION SYSTEM

– AIR CONDITIONER MODULE AND SENSORS

– SYSTEM DIAGRAM

– CONFIGURATION AND FUNCTIONS

– AIR CONDITIONER CONTROLLER UNIT

– SUNSENSOR

– ACTIVE INCAR / HUMIDITY SENSOR: AI SENSOR

– AMBIENT TEMPERATURE SENSOR

– WATER TEMPERATURE SENSOR

– POWER TRANSISTOR

– MODE DOOR ACTUATOR

– IN/EX – AIR DOOR ACTUATOR

– AIR MIX DOOR ACTUATOR

– THERMO AMP (INTAKE SENSOR)

– FFH (FUEL FIRED HEATER) SYSTEM

– PTC(POSITIVE TEMPERATURE COEFFICIENT)

– SELF DIAGNOSIS (ONLY FOR FATC A/C CONTROLLER)

– TROUBLE DIAGNOSIS

– AMBIENT TEMPERATURE SENSOR

– WATER TEMPERATURE SENSOR

– POWER TRANSITOR

– MODE DOOR ACTUATOR

– IN/EX-AIR DOOR ACTUATOR

– AIR MIX DOOR ACTUATOR

– THERMO AMP (INTAKE SENSOR)

– AIR CONDITONER MODULE ASSEMBLY

– A/C CONTROLLER SWITCH AND ACTIVE INCAR/HUMIDITY SENSOR

– AIR DUCT ASSEMBLY

– CONDENSER ASSEMBL

– RECEIVER DRYER ASSEMBLY

– FUEL PUMP

– AMBIENT TEMPERATURE SWITCH

– FFH ASSEMBLY

– PTC

ECU-GASOLINE

DIAGRAMS AND CONECTORS

Avaliações

Não há avaliações ainda.